2026 Best Polyester Hot Melt Adhesive Options for Your Projects?

In the ever-evolving world of adhesives, finding the right option for your projects is crucial. Polyester hot melt adhesive is gaining popularity due to its versatility and performance. Expert John Smith, a leading figure in the adhesive industry, states, “The right adhesive can make or break your project.” This highlights the importance of selecting the best adhesive for specific applications.

Polyester hot melt adhesive offers unique benefits such as strong bonding and quick setting times. Industries ranging from furniture manufacturing to packaging increasingly rely on this adhesive. However, it is essential to be aware that not all polyester hot melt adhesives are created equal. Some may not meet specific project requirements, leading to potential issues.

Choosing the best polyester hot melt adhesive involves careful consideration. Factors like temperature resistance and bond strength play significant roles. Understanding project needs is vital. Often, users underestimate the significance of selecting the right product. Thus, reviewing top options for 2026 will help in making informed decisions and ensuring project success.

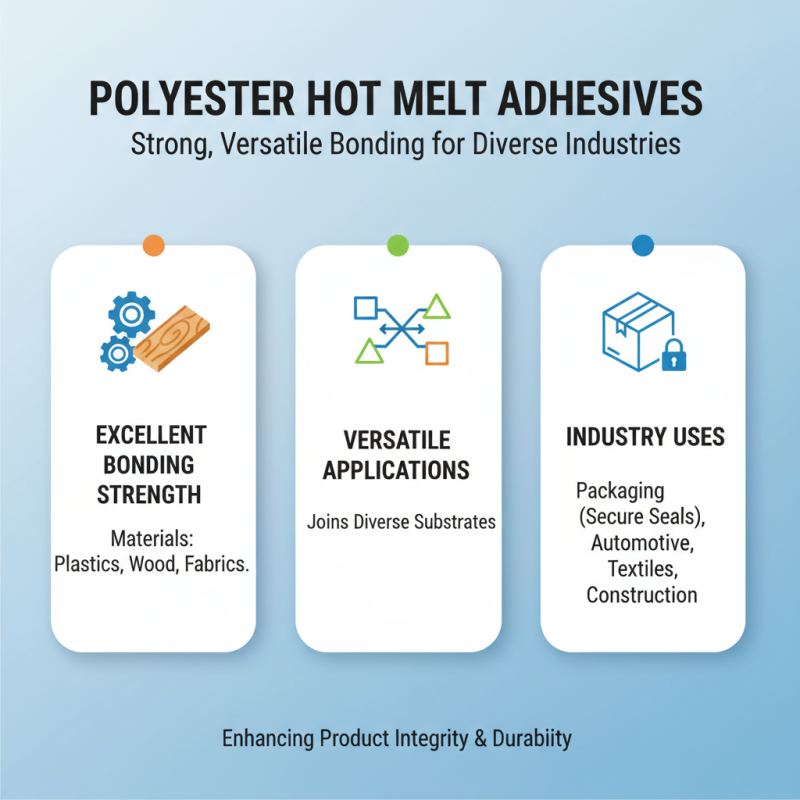

2026 Overview of Polyester Hot Melt Adhesives in Industry Applications

Polyester hot melt adhesives have gained significant traction in various industries. These adhesives offer excellent bonding strength and versatility. They can bond materials like plastics, wood, and fabrics effectively. The ability to work across diverse substrates makes them ideal for many applications. In packaging, for example, they ensure that containers are securely sealed. This is crucial for product integrity.

In automotive and construction sectors, polyester adhesives provide durability and reliability. They withstand harsh environmental conditions. However, not all polyester adhesives are the same. It can be challenging to choose the right one for a specific application. Some may not perform well under extreme temperatures. This can lead to unsatisfactory results. Thorough testing and evaluation are essential to ensure the right match for your project needs.

The manufacturing process of these adhesives also plays a role. Variations in formulation can affect performance. Some products might not adhere well to certain surfaces. Users often need to experiment to find the best fit. It's a learning curve that requires patience. Not every project will yield perfect results at first. This reflects the need for ongoing research and development in this field.

Key Properties and Benefits of Polyester Hot Melt Adhesives for Projects

Polyester hot melt adhesives offer various benefits for projects across different industries. Their excellent bonding strength makes them suitable for wood, plastics, and even textiles. They can withstand temperature fluctuations, making them ideal for both indoor and outdoor use. These adhesives dry quickly, allowing for faster project completion.

One notable property of polyester adhesives is their flexibility. This allows them to adapt to the expansion and contraction of different materials. However, their performance can vary based on environmental conditions. Humidity and temperature can affect adhesion quality. It’s crucial to conduct tests to ensure optimal results.

In addition, polyester hot melt adhesives are known for their resistance to chemicals. This makes them suitable for applications in automotive and packaging industries. Yet, users should be aware of the specific requirements of their projects. Not every formulation will fit every task. So, understanding the unique properties of various adhesives is essential for achieving the best outcome.

2026 Best Polyester Hot Melt Adhesive Options

Market Trends: Leading Manufacturers and Innovations in 2026

In 2026, the polyester hot melt adhesive market is witnessing innovative trends. Manufacturers are increasingly focused on developing adhesives that offer greater strength and flexibility. This shift is driven by diverse applications in industries like textiles, packaging, and construction. Modern formulations are also environmentally friendly, meeting growing sustainability demands.

Emerging technologies play a key role in these advancements. Many companies are exploring bio-based materials for adhesive production. This move not only reduces environmental impact but also enhances performance. However, some challenges remain, such as the consistency of quality across batches. Producers must often navigate these complexities in their quest for better products.

Market leaders are also using smart technologies for production. Automated systems and real-time monitoring help ensure precision and efficiency. Yet, there’s a constant need for improvement. Addressing issues like adhesive aging and its effects on performance continues to be a focus. As manufacturers adapt, the landscape evolves, pushing boundaries while sometimes falling short of expectations.

Comparative Analysis of Performance: Polyester vs. Other Adhesive Types

When comparing polyester hot melt adhesives to other types, performance is often a key factor. Polyester adhesives offer superior strength and thermal resistance. A recent industry report noted that polyester adhesives maintained over 90% bond strength even at elevated temperatures. This makes them ideal for applications requiring durability.

In contrast, some traditional adhesives may start to lose their bond at lower temperatures. For example, PVA and rubber-based adhesives typically show significant degradation in high heat. The need for consistent performance in various conditions makes polyester a strong contender. However, one should consider the specific project requirements. Some adhesives, like polyurethane, excel in flexibility but lack the sheer strength of polyester.

Cost is another aspect to reflect on. Polyester adhesives can be pricier than others, sometimes by 15-20%. Balancing budget and performance is crucial. Users should assess whether the long-term benefits of polyester justify the initial investment. Overlooking this aspect could lead to project delays due to adhesive failure.

Cost Considerations and Economic Impact of Using Hot Melt Adhesives

Hot melt adhesives have grown in popularity for various projects, from manufacturing to arts and crafts. When considering cost, hot melt adhesives are often more economical compared to traditional adhesives. A report by the Adhesive and Sealant Council indicates that the average cost of hot melt adhesives has decreased by about 15% in the past five years. This reduction provides an attractive option for businesses looking to cut overhead costs.

However, the economic impact of using hot melt adhesives can vary. While upfront costs may be lower, it’s essential to account for performance and durability. Inconsistent application may lead to product failures and increase waste. Studies show that projects using high-quality hot melt adhesives can experience up to 20% less waste, ultimately saving money.

Tips: Always conduct small-scale tests when switching adhesives. Another point to consider is machine compatibility. A mismatch can lead to increased maintenance costs. Invest time in research to ensure you select the right adhesive for your specific project needs. Look for suppliers that provide technical support. This could make a significant difference.

Related Posts

-

What is Polyester Hot Melt Adhesive and Its Key Applications

-

2025 Top Polyester Hot Melt Adhesive Trends and Innovations You Should Know

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

How to Effectively Use PUR Hot Melt Adhesive for Your Projects

-

10 Essential Tips for Using Polyamide Hot Melt Adhesive Effectively?

-

Top Uses and Benefits of PUR Hot Melt Adhesive in 2025