Top Uses and Benefits of PUR Hot Melt Adhesive in 2025

As industries continue to evolve in 2025, the demand for advanced adhesive technologies is soaring, particularly the use of PUR Hot Melt Adhesive. Recent market analysis reveals that the global hot melt adhesive market is projected to reach USD 7.6 billion by 2027, with PUR hot melt adhesives gaining traction due to their exceptional bond strength and versatility across various applications. This rising trend exemplifies the shift towards sustainable and efficient bonding solutions that can withstand rigorous conditions, highlighting the importance of PUR hot melt adhesives in modern manufacturing processes.

According to Dr. Emily Chang, a leading expert in adhesive technologies, "The versatility and performance of PUR Hot Melt Adhesive allow manufacturers to explore innovative designs and improve production efficiency." Her insights emphasize how these adhesives not only enhance product longevity but also contribute to reduced production waste, aligning with industry goals for sustainability. As companies continuously seek to optimize their operations, the growth of PUR Hot Melt Adhesive is set to play a pivotal role in transforming bonding methods across industries such as packaging, woodworking, and automotive sectors.

This introduction to the top uses and benefits of PUR Hot Melt Adhesive in 2025 provides a foundational understanding of its impact in the adhesive landscape. By leveraging the unique characteristics of PUR technology, industries can drive efficiency while meeting the increasing consumer demand for durable and eco-friendly products.

Key Characteristics of PUR Hot Melt Adhesive in 2025

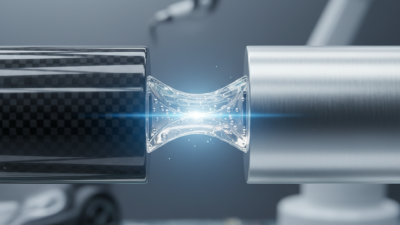

PUR (Polyurethane Reactive) hot melt adhesive has gained significant traction in various industries due to its exceptional characteristics. As we approach 2025, the unique properties of PUR hot melt adhesives are projected to further transform the manufacturing and assembly processes. One of the most notable characteristics is its strong adhesion to a wide range of substrates, including difficult materials such as plastics and metals. According to industry reports, PUR adhesives can deliver initial bond strengths that are often 50% stronger than traditional hot melts, making them ideal for applications demanding durability and longevity.

Another key feature of PUR hot melt adhesive is its versatility in application conditions, including the ability to perform effectively under varying temperatures and humidity levels. This adaptability is crucial, particularly in industries like automotive and construction, where exposure to moisture and temperature fluctuations is common. A study by the Adhesive and Sealant Council (ASC) indicates that the demand for moisture-resistant adhesives is expected to rise by over 30% by 2025, further underscoring the importance of PUR adhesives in meeting these evolving performance criteria. Moreover, the environmentally friendly profile of PUR adhesives, which typically contain lower VOCs (Volatile Organic Compounds), aligns with the growing trend towards sustainability in manufacturing. As companies increasingly prioritize eco-friendly solutions, PUR hot melt adhesives are set to play a pivotal role in future operations.

Primary Applications of PUR Hot Melt Adhesive Across Industries

PUR hot melt adhesive has gained significant traction across various industries due to its unique properties and performance advantages. One of its primary applications lies in the furniture industry, where it is used for laminating surfaces and assembling components. The adhesive offers strong bonding capabilities that withstand stress and strain, making it ideal for high-use items like chairs and tables. Its ability to provide a clean and aesthetically pleasing finish also contributes to its popularity amongst manufacturers seeking to enhance product quality.

In the packaging sector, PUR hot melt adhesive is favored for its versatility and reliability. Used in carton sealing, label application, and film bonding, it provides a durable bond that maintains its integrity even under varying temperatures and humidity levels. Additionally, the adhesive's rapid setting time helps streamline production processes, improving efficiency without compromising on quality. Furthermore, its application in the automotive industry, particularly in composite bonding and assembly, showcases its ability to bond dissimilar materials, contributing to the overall durability and safety of vehicle components.

Comparative Advantages of PUR Hot Melt Adhesive Over Traditional Adhesives

PUR hot melt adhesive offers several comparative advantages over traditional adhesives that make it a superior choice for various applications in 2025. One significant benefit is its exceptional heat resistance and durability. Unlike conventional adhesives, which may lose bond strength when exposed to high temperatures, PUR hot melt adhesives maintain their integrity, ensuring long-lasting performance in demanding environments. This property is particularly crucial for industries such as automotive and construction, where materials are often subjected to extreme conditions.

Another key advantage of PUR hot melt adhesives is their versatility and ease of application. They can bond a wide range of substrates, including plastics, metals, and natural materials, making them suitable for diverse projects. The quick setting time allows for faster production processes, reducing downtime and increasing efficiency. Furthermore, PUR adhesives exhibit a strong bonding strength even in challenging conditions, such as moisture or varying temperatures, setting them apart from traditional adhesive options that may struggle under similar circumstances. This unique combination of properties ensures that manufacturers can rely on PUR hot melt adhesives for consistent results across multiple applications.

Environmental Impact and Sustainability of PUR Hot Melt Adhesives

In 2025, the use of PUR (polyurethane reactive) hot melt adhesives is increasingly recognized for its environmental sustainability. These adhesives contribute to reduced waste through precise application, minimizing excess material. According to a recent industry report, PUR hot melts can help reduce waste by up to 30% compared to traditional adhesives. The ability of PUR adhesives to bond effectively at lower quantities means less product is needed, which directly translates into a lower environmental footprint during manufacturing processes.

Moreover, the chemical composition of PUR hot melts allows for VOC (volatile organic compounds) emissions to be significantly lower than those of solvent-based adhesives. A study conducted by the Adhesive and Sealant Council revealed that PUR adhesives can emit up to 80% fewer VOCs, making them a preferable choice for manufacturers aiming to adhere to stricter environmental regulations. This lower emission level not only benefits the environment but also promotes healthier working conditions within production facilities.

Tips: When selecting a PUR adhesive, consider opting for formulations that are labeled low-VOC or zero-VOC to enhance sustainability efforts. Additionally, ensure that your application process is optimized to leverage the precise bonding capabilities of PUR hot melts, which can lead to further material savings and reduced environmental impact. Lastly, explore how incorporating recyclability measures into your adhesive processes can contribute to a circular economy.

Top Uses and Benefits of PUR Hot Melt Adhesive in 2025

The chart above illustrates the market share distribution of PUR Hot Melt Adhesives across various industries in 2025. As seen, the furniture industry leads with 25% market share, followed by construction and automotive sectors, highlighting the versatility and growing adoption of PUR technologies in sustainable applications.

Future Trends and Innovations in PUR Hot Melt Adhesive Technology

The landscape of PUR (Polyurethane Reaction) hot melt adhesives in 2025 is set to be influenced significantly by advancements in technology and growing environmental consciousness.

One of the key trends is the development of bio-based and sustainable PUR formulations, which not only enhance performance but also prioritize eco-friendliness. These innovations are driven by both regulatory pressures and consumer demand for greener products, prompting manufacturers to explore renewable resources and reduce their carbon footprints.

Another notable trend is the integration of smart technology into PUR hot melt adhesives. This includes the incorporation of sensors that can provide real-time feedback on bond integrity or environmental conditions. Such enhancements enable users to monitor application processes more effectively, leading to improved quality control and reduced waste.

Furthermore, as automation becomes more prevalent in manufacturing, the compatibility of PUR adhesives with automated dispensing systems is expected to improve, facilitating faster production cycles and greater efficiency. The convergence of these elements illustrates a promising future for PUR hot melt adhesives, characterized by innovation, sustainability, and enhanced performance.

Related Posts

-

Top 10 Tips for Using Polyester Hot Melt Adhesive Effectively

-

Top Reasons to Choose Modified Acrylate Adhesive for Your Projects

-

What is Crylate Adhesive? Understanding Its Uses and Benefits

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions

-

2025 Top Polyester Hot Melt Adhesive Trends and Innovations You Should Know