How to Choose the Best Beer Bottle Labeling Adhesives for Your Brewery

When it comes to the craft of brewing, the importance of effective branding cannot be overstated, and the first point of contact for consumers is often the beer bottle label. Choosing the right Beer Bottle Labeling Adhesives can significantly impact the overall appeal and functionality of your product. According to industry expert James Brewster, "Choosing the right adhesive is just as crucial as the design of the label itself; it ensures that your hard work shines without any distractions."

The adhesive must not only perform well under various storage conditions but also align with the aesthetic goals of the brewery. With an array of options available in the market, understanding the properties and suitability of each type of adhesive is essential. This decision influences not only the visual presentation but also the consumer's experience and satisfaction.

In this article, we will explore the key factors to consider when selecting Beer Bottle Labeling Adhesives, from durability and temperature resistance to ease of application. Armed with this knowledge, breweries can make informed decisions that reflect their brand's identity while ensuring that their product stands out on the shelf.

Understanding the Importance of Beer Bottle Labeling Adhesives

The importance of beer bottle labeling adhesives cannot be overstated in the brewing industry. These adhesives play a crucial role in ensuring that labels adhere effectively to bottles, maintaining the integrity and quality of the product. A well-applied label not only conveys essential information about the beer, such as its name, ingredients, and alcohol content, but it also serves as a first impression for consumers. Labels that peel off or become damaged can lead to a negative perception of the brand, impacting customer trust and ultimately sales.

Moreover, the choice of adhesive can significantly affect the production process. Adhesives must be compatible with the various bottle materials and withstand the conditions of storage and transportation. Factors such as temperature fluctuations, humidity levels, and exposure to light can influence the performance of the adhesive. Therefore, selecting the right beer bottle labeling adhesive is not merely a matter of aesthetics; it is essential for ensuring that the labels remain intact throughout their lifecycle. This consideration allows brewers to present their product professionally while also safeguarding their brand reputation in a competitive market.

Types of Adhesives Used in Beer Bottle Labeling

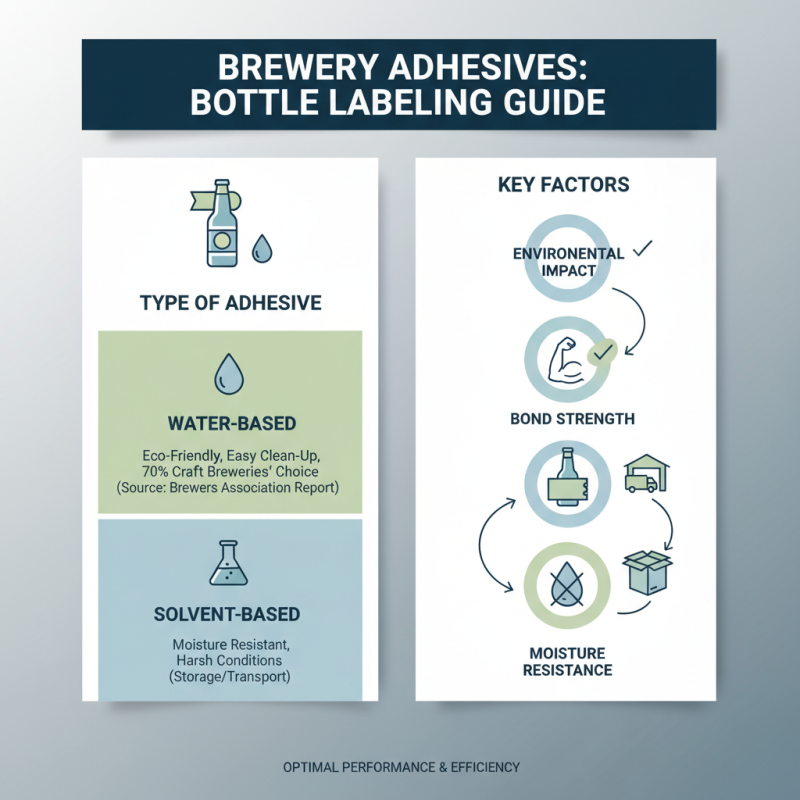

When it comes to beer bottle labeling, the choice of adhesive can significantly impact both the efficiency of the labeling process and the quality of the final product. There are primarily three types of adhesives utilized in the beer bottle labeling industry: water-based, solvent-based, and hot melt adhesives. Each type has its unique properties and applications, making it crucial for breweries to select the right one based on their specific needs.

Water-based adhesives are favored for their environmental benefits and ease of cleaning, making them ideal for breweries that prioritize sustainability. According to a 2021 market report, water-based adhesives account for more than 30% of the adhesive market in the beverage sector, highlighting a growing trend towards eco-friendly practices.

In contrast, solvent-based adhesives offer stronger bonding and durability under varying conditions, which is especially crucial for bottles exposed to moisture or cold temperatures. Data from the Adhesives and Sealants Market Report indicates that solvent-based adhesives comprise approximately 40% of the market share, proving their effectiveness in ensuring labels remain intact during the handling and distribution phases.

Hot melt adhesives, another popular choice in labeling, provide instant adhesion and are highly versatile, suitable for various substrate types. A recent study revealed that hot melt adhesives are rapidly gaining popularity, with an annual growth rate of 5% in the beverage labeling segment. This rise can be attributed to advances in adhesive technology that enhance their performance in high-speed bottling lines. Understanding these options allows breweries to make informed decisions that align with their production methods and brand values.

Factors to Consider When Choosing Adhesives for Your Brewery

When selecting the best beer bottle labeling adhesives for your brewery, several key factors should be considered to ensure optimal performance and efficiency. First, the type of adhesive is paramount; water-based adhesives are commonly preferred due to their eco-friendliness and ease of cleaning. According to a report by the Brewers Association, approximately 70% of craft breweries favor water-based solutions because they offer good bond strength while minimizing environmental impact. However, solvent-based adhesives may be more suitable for certain conditions where moisture resistance is crucial, especially during storage and transportation.

Another important consideration is the temperature resistance of the adhesive. The adhesive must maintain its performance under varying temperatures encountered throughout the brewing and bottling process. As noted in industry guidelines, adhesives need to withstand both cold temperatures during refrigeration and higher temperatures during pasteurization without losing adhesion. This information is critical, as improper adhesive selection can lead to label failure, resulting in costly reworks and wasted production time. Additionally, breweries should evaluate the drying time of the adhesives, as quicker-drying options can significantly enhance bottling line efficiency, allowing for greater throughput.

Finally, the compatibility of adhesives with various label substrates cannot be overlooked. Different materials, such as paper and plastic, may require specific adhesive formulations to ensure strong bonding and longevity. Industry studies highlight that mismatched substrates and adhesives contribute to a high percentage of labeling failures, which can negatively impact brand presentation. Hence, understanding the characteristics of your chosen labels alongside the adhesive properties will play a vital role in establishing a labeling process that is both effective and visually appealing.

Evaluating Environmental Impact and Sustainability of Adhesives

When selecting beer bottle labeling adhesives, breweries must weigh the environmental impact and sustainability of their choices. Traditional adhesives often contain harmful solvents and oils, contributing to pollution during production and disposal. In a recent industry study, it was reported that nearly 30% of adhesives used in packaging fail to meet current sustainability standards, leading to a significant carbon footprint across supply chains. Prioritizing eco-friendly options can help breweries not only comply with regulations but also enhance their brand image, appealing to an increasingly environmentally conscious consumer base.

Sustainable adhesive choices include bio-based and water-based formulations that not only reduce volatile organic compounds (VOCs) but also make use of renewable resources. According to an analysis by the Adhesive and Sealant Council, adopting such alternatives can lead to a reduction in greenhouse gas emissions of up to 50%. Furthermore, the lifecycle assessment indicates that using sustainable adhesives can decrease water usage and energy consumption during the production process. For breweries, this shift not only fosters environmental stewardship but can also result in long-term cost savings, as more efficient production methods are implemented.

How to Choose the Best Beer Bottle Labeling Adhesives for Your Brewery - Evaluating Environmental Impact and Sustainability of Adhesives

| Adhesive Type | Environmental Impact | Sustainability Rating | Temperature Resistance | Application Method |

|---|---|---|---|---|

| Water-based Adhesive | Low VOC, biodegradable | High | Up to 70°F (21°C) | Roller or Spray |

| Solvent-based Adhesive | Higher VOC, potential environmental concerns | Medium | Up to 100°F (38°C) | Brush or Roller |

| Hot Melt Adhesive | Low environmental impact if sourced sustainably | Medium | Up to 150°F (65°C) | Automatic or Manual Application |

| Biodegradable Adhesive | Completely biodegradable | Very High | Up to 90°F (32°C) | Roller or Brush |

Testing and Application Techniques for Optimal Label Adhesion

When it comes to ensuring optimal label adhesion for beer bottles, the choice of adhesive is crucial. Industry research suggests that approximately 70% of label failures occur due to inadequate adhesion, which can significantly impact branding and consumer perception. Testing adhesive formulations in controlled environments, such as temperature variations and humidity levels, is essential for determining their performance. For instance, a study published in the Journal of Adhesion Science reported that adhesives with high shear strength showed more than a 30% improvement in initial tack, indicating longer-lasting results against peeling and lifting.

Application techniques also play a pivotal role in achieving superior label adhesion. Consistent application pressure and uniform adhesive coating thickness are paramount for effective bonding. According to data from the Adhesive and Sealant Council, an effective application technique can enhance the performance of even moderate adhesives, leading to a 20% increase in label longevity. Additionally, pre-conditioning bottles by cleaning and drying them thoroughly can help improve surface energy, thereby optimizing adhesion. Brewers are encouraged to regularly conduct adhesion tests on their bottles under various conditions to assess the effectiveness of their chosen adhesives and application methods, ultimately enhancing brand integrity and customer satisfaction.

Related Posts

-

Top 10 Tips for Using Polyester Hot Melt Adhesive Effectively

-

What is Crylate Adhesive? Understanding Its Uses and Benefits

-

Top Uses and Benefits of PUR Hot Melt Adhesive in 2025

-

2025 Top Polyester Hot Melt Adhesive Trends and Innovations You Should Know

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions