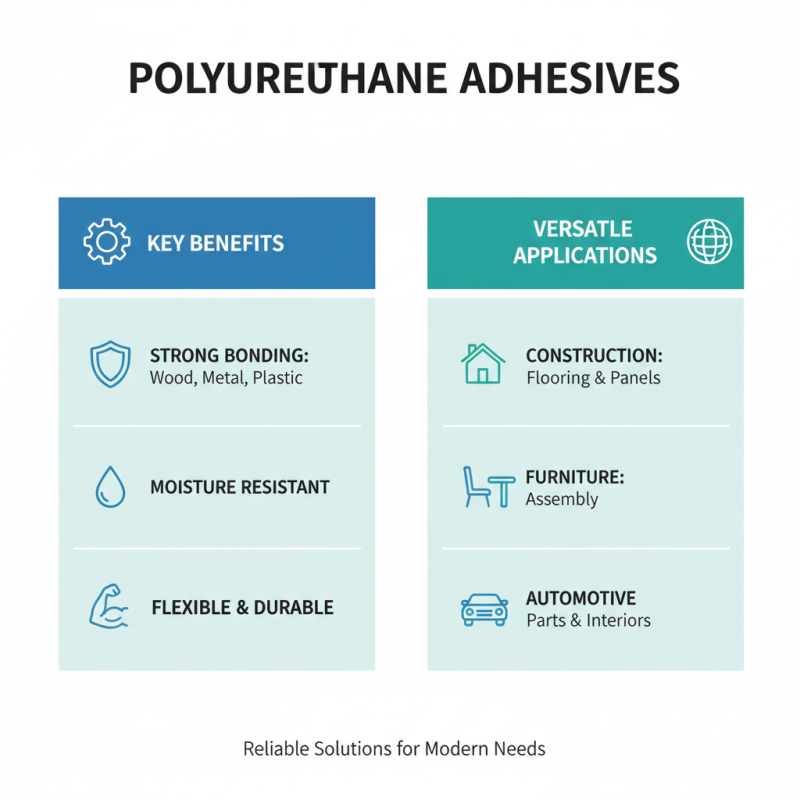

Why Choose Polyurethane Adhesive for Your Projects?

Polyurethane Adhesive has become a go-to choice for many projects in various industries. According to Dr. Emily Carter, a renowned expert in adhesive technology, "Polyurethane Adhesive offers unmatched versatility and strength for diverse applications." This set of properties makes these adhesives highly favored among professionals.

This adhesive type is known for its excellent bonding capabilities. It provides a durable solution that withstands varying temperatures and humidity levels. Users can achieve strong, lasting bonds on a range of materials, including wood, metal, and plastic. Nevertheless, some challenges remain. Proper surface preparation is crucial. Missteps here can lead to bond failure.

Moreover, choosing the right Polyurethane Adhesive can sometimes be overwhelming. Many options exist, and not all are suitable for every task. Users should reflect on specific project needs before deciding. In conclusion, the right choice can make a significant difference. Prioritize durability and application suitability when selecting Polyurethane Adhesive.

Benefits of Polyurethane Adhesives in Construction and Manufacturing

Polyurethane adhesives have gained popularity in construction and manufacturing due to their remarkable benefits. These adhesives excel in bonding a variety of materials, including wood, metal, and plastic. Their versatility means they can be used in numerous applications, from furniture assembly to automotive parts.

One of the standout features of polyurethane adhesives is their strength. Once cured, they create a robust bond that withstands heavy loads and extreme weather conditions. This makes them ideal for both indoor and outdoor use. However, achieving the perfect bond may require surface preparation. Not all surfaces bond equally well. Some materials may need sanding or cleaning to ensure a strong connection.

Another benefit lies in their flexibility. Polyurethane adhesives can absorb shock and vibration, ideal for dynamic environments. This elasticity can prevent cracking over time. Yet, users must be cautious; prolonged exposure to moisture can weaken the bond. Using these adhesives effectively may require some trial and error. This learning curve can lead to improved techniques and better results in future projects.

Comparative Strength and Durability of Polyurethane vs. Other Adhesives

When deciding on an adhesive for your projects, polyurethane stands out for its strength and durability. Unlike some traditional adhesives, polyurethane bonds a variety of surfaces effectively. It performs exceptionally well in extreme conditions. Whether exposed to moisture or fluctuating temperatures, polyurethane maintains its integrity. This resistance makes it ideal for both indoor and outdoor applications.

Polyurethane adhesives offer superior flexibility compared to other options. This flexibility helps to absorb shocks and vibrations. It reduces the chances of the bond breaking under stress. Moreover, polyurethane adheres well to porous materials, enhancing its versatility. However, it can have a longer curing time, which may be a drawback for projects needing quick fixes.

**Tip:** Always ensure surfaces are clean and dry before application. Even small contaminants can disrupt the bond.

Not all applications require the strongest adhesive. In some cases, a simpler option may suffice. Evaluate your project’s specific needs carefully before deciding. Make sure to test a small area first to see if the adhesive works as expected. The right choice greatly depends on the project and environment.

Why Choose Polyurethane Adhesive for Your Projects? - Comparative Strength and Durability of Polyurethane vs. Other Adhesives

| Adhesive Type | Strength (MPa) | Durability (Years) | Temperature Resistance (°C) | Water Resistance |

|---|---|---|---|---|

| Polyurethane | 20-30 | 10-20 | -40 to 80 | Excellent |

| Epoxy | 25-40 | 5-25 | -50 to 120 | Good |

| Polyvinyl Acetate | 10-20 | 1-5 | -15 to 60 | Fair |

| Cyanoacrylate | 15-25 | 2-3 | -20 to 80 | Poor |

Environmental Considerations of Using Polyurethane Adhesives

Polyurethane adhesives have gained popularity due to their robust bonding capabilities. However, their environmental impact warrants closer examination. According to the U.S. EPA, adhesive manufacturing contributes notable emissions, particularly volatile organic compounds (VOCs). Polyurethane adhesives, in some formulations, can release harmful VOCs during application and curing. These compounds may pose health risks, harming air quality.

Despite their advantages, the environmental footprint of polyurethane adhesives can be a concern. A report by the Adhesive and Sealant Council states that alternatives like water-based adhesives significantly reduce harmful emissions. The push for greener options is essential. The rising demand for eco-friendly materials drives innovation in the industry. Researchers are exploring low-VOC formulations, enhancing safety without sacrificing performance.

Balancing performance and environmental impact is challenging. While polyurethane adhesives excel in strength, manufacturers must address leaks during application. An industry study highlighted that better handling practices could mitigate environmental issues. Optimizing the supply chain could lead to less waste. Users must weigh the benefits against potential environmental drawbacks and opt for the best practices available.

Application Versatility: Industries Relying on Polyurethane Adhesives

Polyurethane adhesives have gained popularity across various industries due to their impressive application versatility. In construction, these adhesives are often used for bonding materials like wood, metal, and glass. The strong bonding capabilities allow for durable structures that can withstand changing weather conditions. Some projects, however, might require careful surface preparation, or the adhesive may not perform well with certain finishes. This can lead to frustrations during application.

In automotive manufacturing, polyurethane adhesives play a crucial role in assembling vehicle parts. They are used in bonding windshields, panels, and underbody components. The flexibility and durability of these adhesives help maintain vehicle integrity over time. Yet, improper mixing ratios can lead to weak bonds. This inconsistency can cause delays in production, forcing teams to rethink their approach.

The furniture industry also benefits from polyurethane adhesives. They are ideal for various materials like laminates, veneers, and solid wood. This versatility allows craftsmen to explore creative designs. However, some users might find that not all polyurethane adhesives are suitable for outdoor furniture, which could result in unexpected failures. Addressing these challenges requires a commitment to testing and quality assurance in every project.

Cost-Effectiveness of Polyurethane Adhesives in Long-Term Projects

Polyurethane adhesives shine in long-term projects, primarily due to their cost-effectiveness.

These adhesives bond various materials, ensuring durability and resilience. They perform well in diverse conditions, resisting moisture, heat, and chemicals. This resilience can ultimately reduce the need for frequent repairs and replacements, saving you money over time.

Unexpected challenges can arise when using polyurethane adhesives. The initial application may require specific techniques to achieve optimal results. Making sure to follow the manufacturer's instructions is crucial. Some users have reported difficulties in adhesion due to poor surface preparation. It’s essential to clean surfaces thoroughly and ensure they are dry before application. Otherwise, the bond may not hold.

Furthermore, while polyurethane adhesives offer great value, patience is necessary. They can take longer to cure compared to other options, which could delay project timelines. Nonetheless, this extended curing time contributes to their strength and reliability. If you're invested in a long-term project, the initial wait can lead to lasting benefits and overall satisfaction.

Related Posts

-

How to Use Polyurethane Adhesive for Strong and Durable Bonds

-

What is Crylate Adhesive? Understanding Its Uses and Benefits

-

How to Choose the Right Crylate Adhesive for Your Project Needs

-

Top Reasons to Choose Modified Acrylate Adhesive for Your Projects

-

How to Choose the Best Beer Bottle Labeling Adhesives for Your Brewery

-

Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions