How to Choose the Right Crylate Adhesive for Your Project Needs

Choosing the right adhesive for your project can significantly impact the effectiveness, durability, and overall success of your work. Among various adhesive options, Crylate Adhesives stand out due to their unique properties and versatile applications. These adhesives are built on a methacrylate base, offering excellent adhesion to a wide variety of substrates, making them suitable for various industries, including automotive, construction, and consumer goods. As you embark on selecting the right Crylate Adhesive, it’s crucial to consider factors such as curing time, temperature resistance, and bonding strength to ensure you meet the specific demands of your project.

Understanding the characteristics of Crylate Adhesives can guide you through the selection process. These adhesives typically provide rapid curing times, which can expedite production schedules while maintaining high-performance bonds. Additionally, their ability to withstand harsh environmental conditions makes them an ideal choice for applications exposed to extreme temperatures or humidity. By evaluating your project’s requirements and the properties offered by Crylate Adhesives, you can identify the most suitable product to achieve reliable and lasting results.

Factors to Consider When Selecting Crylate Adhesives for Projects

When selecting crylate adhesives for your projects, several key factors should be considered to ensure optimal performance and compatibility with your materials. First, evaluate the specific properties of the adhesive, such as its curing time, bond strength, and resistance to environmental factors like moisture, heat, and chemicals. Each project may have unique demands that require an adhesive with tailored characteristics to achieve the desired results. Understanding these properties will help you make informed decisions that enhance the durability and longevity of your assembled products.

Another critical aspect to consider is the substrate compatibility. Different materials, whether metals, plastics, or ceramics, will react differently with adhesives. It's crucial to assess the surface energy and texture of the substrates involved, as these factors can significantly influence adhesion quality. Additionally, consider the working environment and potential stresses that the bond will encounter; for instance, exposure to UV light can degrade certain adhesives over time. By thoroughly analyzing these factors, you can select a crylate adhesive that meets the specific demands of your project while ensuring a reliable and robust bond.

Comparison of Common Types of Crylate Adhesives and Their Applications

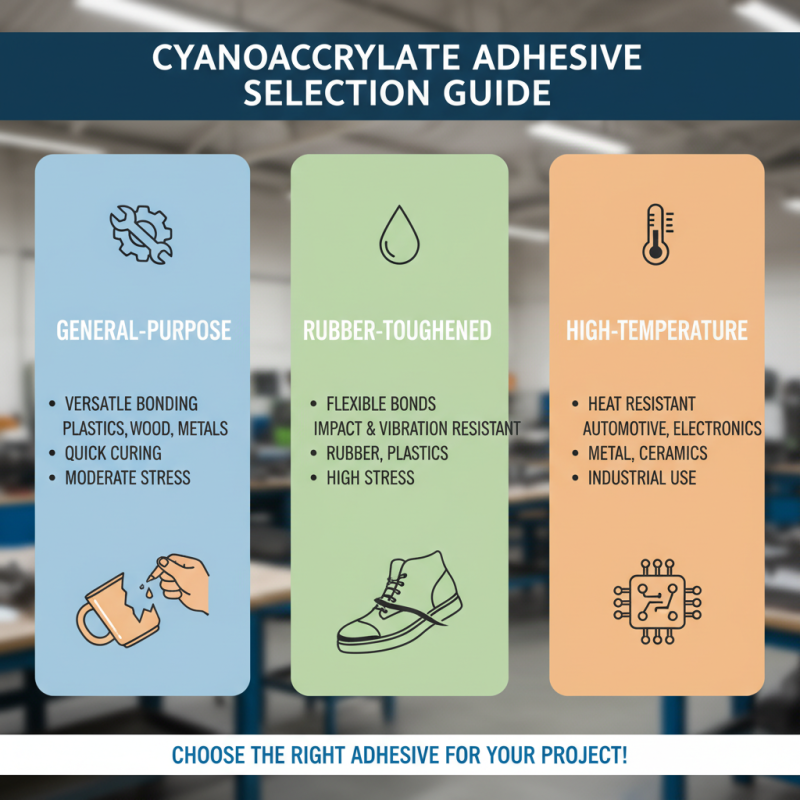

When selecting the appropriate cyanoacrylate adhesive for your specific project, understanding the distinct types available and their applications is crucial. Cyanoacrylate adhesives are commonly classified into several categories based on their formulation and intended use. For instance, general-purpose cyanoacrylates are ideal for a wide range of materials, including plastics, wood, and metals, making them useful for everyday repairs and household tasks. These adhesives typically cure quickly, providing a strong bond but are best used when conditions permit a moderate application of stress.

On the other hand, specialized cyanoacrylate adhesives are formulated to meet particular challenges. For example, flexible cyanoacrylates maintain some degree of elasticity after curing, making them suitable for bonding dissimilar materials that experience movement or vibration. Additionally, high-temperature cyanoacrylates are designed to withstand extreme heat, which is essential for applications in automotive or aerospace industries. Understanding these variations allows users to choose an adhesive that not only bonds effectively but also aligns with the demands of their project, ensuring durability and efficiency.

Understanding the Bond Strength Ratings of Crylate Adhesives

When selecting the appropriate crylate adhesive for your project, understanding the bond strength ratings is crucial. Crylate adhesives are known for their versatility and strong bonding capabilities, which are quantified through various bond strength ratings. These ratings indicate how well the adhesive can hold up under different conditions, such as tension, shear, and temperature fluctuations. It's important to note that the specific application will dictate which rating is most relevant, as different projects may require different types of bond strengths to perform effectively.

In addition to bond strength ratings, one should also consider the factors that affect performance, including substrate materials and environmental conditions. For instance, some crylate adhesives provide better performance on porous surfaces, while others excel with non-porous materials. The intended use of the adhesive—whether for indoor applications, outdoor exposure, or high-stress environments—will also influence your choice. Thoroughly reviewing the technical specifications and recommended applications of each adhesive will aid in making an informed decision, ensuring that the bond strength meets the demands of your specific project.

Bond Strength Ratings of Crylate Adhesives

Evaluating Environmental Resistance Properties of Crylate Adhesives

When selecting the right crylate adhesive for your project, environmental resistance properties play a crucial role in ensuring long-term performance. Crylate adhesives are known for their versatility, but their effectiveness under various environmental conditions can significantly impact the durability of the bond. A report by the Adhesive and Sealant Council highlights that over 60% of adhesive failures in industrial applications can be attributed to insufficient environmental resistance, including moisture, UV exposure, and temperature fluctuations.

Moisture resistance is particularly important for applications in humid environments, where water ingress can compromise bond integrity. Data from a study conducted by the Institute of Adhesion Science indicates that crylate adhesives can maintain their performance in high humidity conditions, with some formulations displaying up to 80% bond strength retention after prolonged exposure. Additionally, UV stability is crucial for outdoor applications. Research has shown that certain crylate formulations have demonstrated excellent UV resistance, maintaining adhesive strength levels above 90% after 1000 hours of exposure.

Thermal stability is another key factor to consider. According to industry analyses, the thermal deformation point for many crylate adhesives ranges from -40°C to 100°C, making them suitable for a variety of environmental conditions. It is essential to evaluate these properties to ensure that the chosen adhesive not only meets the immediate bonding requirements but also withstands the rigors of its intended environment, ultimately leading to enhanced project longevity and performance.

Industry Standards and Certifications for Quality Crylate Adhesives

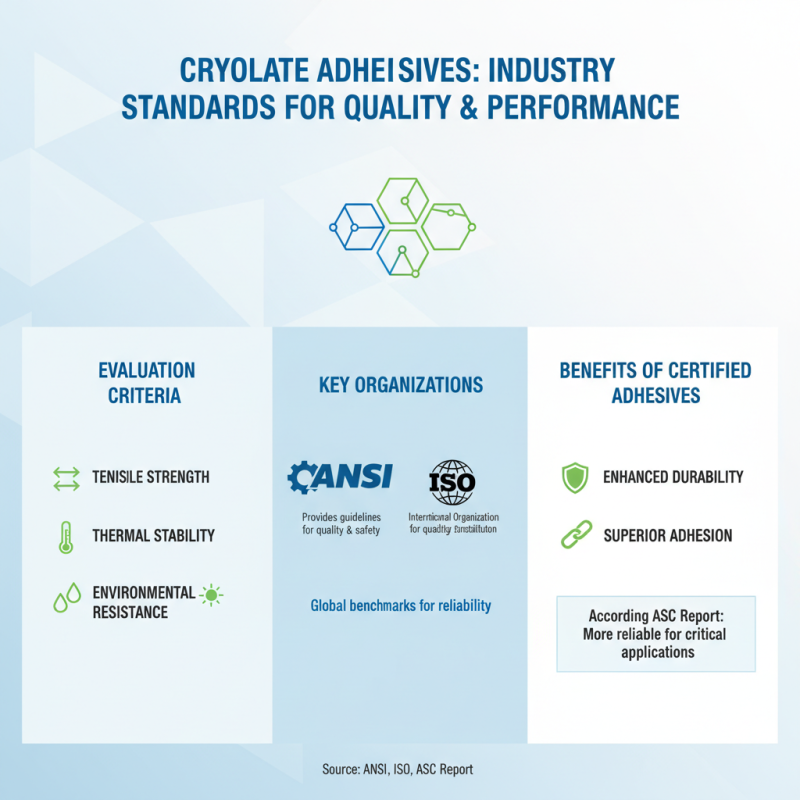

When selecting the right crylate adhesive for your projects, understanding industry standards and certifications is crucial for ensuring quality and performance. Crylate adhesives are evaluated based on various criteria, including tensile strength, thermal stability, and resistance to environmental factors. The American National Standards Institute (ANSI) and International Organization for Standardization (ISO) provide guidelines that help manufacturers assert the quality and safety of their products. According to a recent report by the Adhesive and Sealant Council (ASC), adhesives that meet these industry standards tend to have enhanced durability and adhesion properties, making them more reliable for critical applications.

One important tip when selecting a crylate adhesive is to look for products that have received third-party certifications, such as the ISO 9001 certification. This ensures that the adhesive has undergone rigorous testing and adheres to internationally recognized quality management principles. Additionally, seeking adhesives that comply with eco-labels, like Greenguard, can help ensure that your selection is safe for both users and the environment, which is becoming increasingly important in today’s market.

Another aspect to consider is the adhesive's performance in real-world applications. Studies from the Adhesive and Sealant Council reveal that adhesives with proven track records in various industries, such as automotive and aerospace, offer reliable bonding solutions. Hence, it's beneficial to review case studies or technical data sheets that demonstrate the adhesive's effectiveness in situations similar to your project’s requirements. By focusing on these industry standards and certifications, you can make informed choices that lead to successful outcomes in your projects.

Related Posts

-

Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions

-

What is Crylate Adhesive? Understanding Its Uses and Benefits

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

Top Reasons to Choose Modified Acrylate Adhesive for Your Projects

-

Top Uses and Benefits of PUR Hot Melt Adhesive in 2025

-

How to Choose the Best Beer Bottle Labeling Adhesives for Your Brewery