Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions

In the realm of industrial bonding solutions, the choice of adhesive can significantly influence both performance and longevity. Among various options available, Crylate Adhesive has emerged as a frontrunner, particularly for applications requiring exceptional durability and resilience. According to a report by the Adhesive and Sealant Council, the global adhesive market is projected to reach $50.64 billion by 2026, with crylate formulations increasingly favored for their superior adhesion properties under diverse environmental conditions.

Crylate Adhesive is particularly renowned for its outstanding thermal stability and resistance to moisture, making it ideal for a wide range of applications across industries, including automotive, aerospace, and electronics. A study conducted by Research and Markets indicates that the growing demand for lightweight materials in manufacturing is driving the adoption of advanced bonding solutions like Crylate Adhesive, which provides reliable performance without compromising structural integrity. As industries strive for more efficient and sustainable practices, the long-lasting capabilities of Crylate Adhesive position it as the ultimate choice for durable bonding solutions, ensuring that manufacturers can meet both their operational demands and quality standards.

Key Characteristics of Crylate Adhesive in Bonding Applications

Crylate adhesives have gained significant traction in various industries due to their exceptional bonding characteristics. One of their primary advantages is their rapid curing time, which can be as short as 10 minutes, according to the Adhesive and Sealant Council. This feature is particularly valuable in high-volume production environments, where efficiency is paramount. Additionally, crylate adhesives exhibit excellent adhesion to a wide range of substrates, including metals, plastics, and composites, making them versatile tools for manufacturers. Their adaptability is supported by a market research report from Research and Markets, which indicates that the global demand for crylate-based adhesives is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2021 to 2026.

Another key characteristic of crylate adhesives is their resistance to environmental factors such as moisture and temperature fluctuations. This durability ensures long-lasting bonds even in challenging conditions, making them an ideal choice for applications in automotive, aerospace, and construction sectors. A study published in the Journal of Adhesion Science and Technology noted that crylate adhesives maintain over 80% of their original bond strength in extreme conditions, highlighting their reliability. Furthermore, with advancements in formulation technology, crylate adhesives have become increasingly customizable, allowing for tailored solutions that meet specific performance criteria, elevating their status as a preferred bonding option in modern manufacturing.

Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions

| Characteristic | Description | Benefits |

|---|---|---|

| Fast Setting | Crylate adhesives cure quickly, offering rapid bonding for increased productivity. | Reduces downtime and accelerates manufacturing processes. |

| High Strength | Provides exceptional bonding strength across various substrates. | Ensures durability and longevity of the bonded joints. |

| Chemical Resistance | Resistant to a wide range of chemicals, including solvents and oils. | Ideal for applications in harsh environments. |

| Versatility | Can bond various materials, including plastics, metals, and glass. | Applicable in numerous industries and repair situations. |

| Flexibility | Allows for movement and expansion without compromising the bond. | Prevents cracking and failure in dynamic applications. |

Comparative Analysis of Crylate Adhesive vs. Traditional Adhesives

Crylate adhesives have emerged as a leading choice for bonding solutions, especially when compared to traditional adhesives like epoxies or polyurethanes. According to a report by the Adhesive and Sealant Council, crylate adhesives exhibit superior flexibility and impact resistance, making them ideal for applications that require durability under extreme conditions. While traditional adhesives can become brittle over time, leading to bond failure, crylate adhesives retain their mechanical properties and adhesion strength, even in fluctuating temperature and humidity.

Further analysis indicates that crylate adhesives can achieve bond strengths of over 3000 psi, while traditional adhesives often fall short, with average bond strengths ranging between 1500 to 2500 psi. This stark contrast highlights the advantages of crylate adhesives in industrial applications where strength is paramount. Additionally, crylate systems offer rapid curing times, reducing assembly times significantly. A study published in the Journal of Adhesion Science and Technology noted that crylate adhesives can cure within just minutes, as opposed to traditional counterparts that may require an extended curing period, enhancing productivity in manufacturing processes.

Impact of Crylate Adhesive on Industry-Specific Bonding Durability

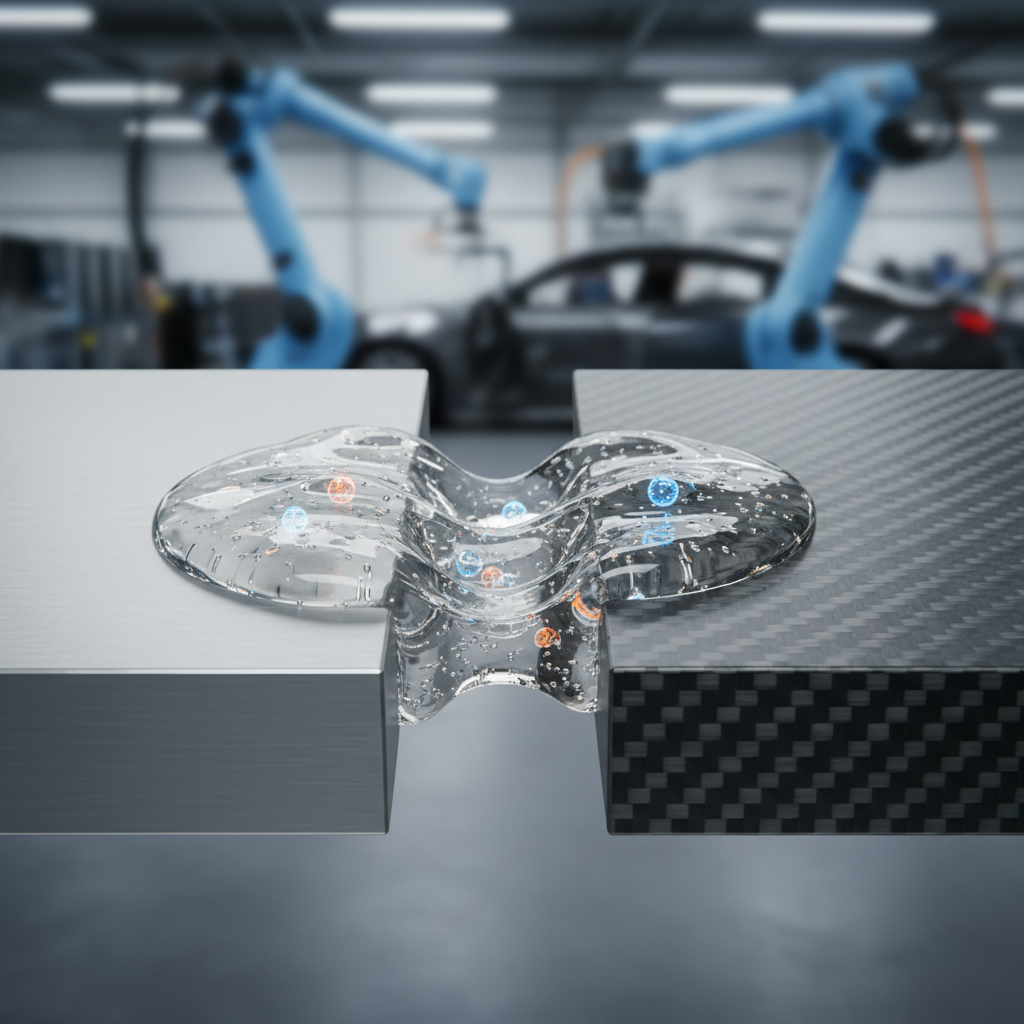

The impact of crylate adhesive on industry-specific bonding durability is significant, making it a preferred choice across various sectors. These adhesives exhibit superior flexibility and resilience, which is essential in environments subject to dynamic mechanical stress. For instance, in the automotive industry, crylate adhesives provide optimal adhesion in structural applications, ensuring components withstand vibrations and thermal fluctuations without compromising their integrity.

Moreover, crylate adhesives are engineered to resist environmental factors such as moisture, heat, and chemicals. This property is particularly advantageous in the aerospace and construction industries, where materials are often exposed to harsh conditions. The ability of crylate adhesives to maintain their bonding strength under these challenges enhances the lifespan of assemblies, reducing the need for frequent repairs or replacements.

Thus, the use of crylate adhesive not only improves the overall safety and reliability of products but also contributes to cost efficiency and sustainability in manufacturing processes.

Statistical Insights into Crylate Adhesive Performance Metrics

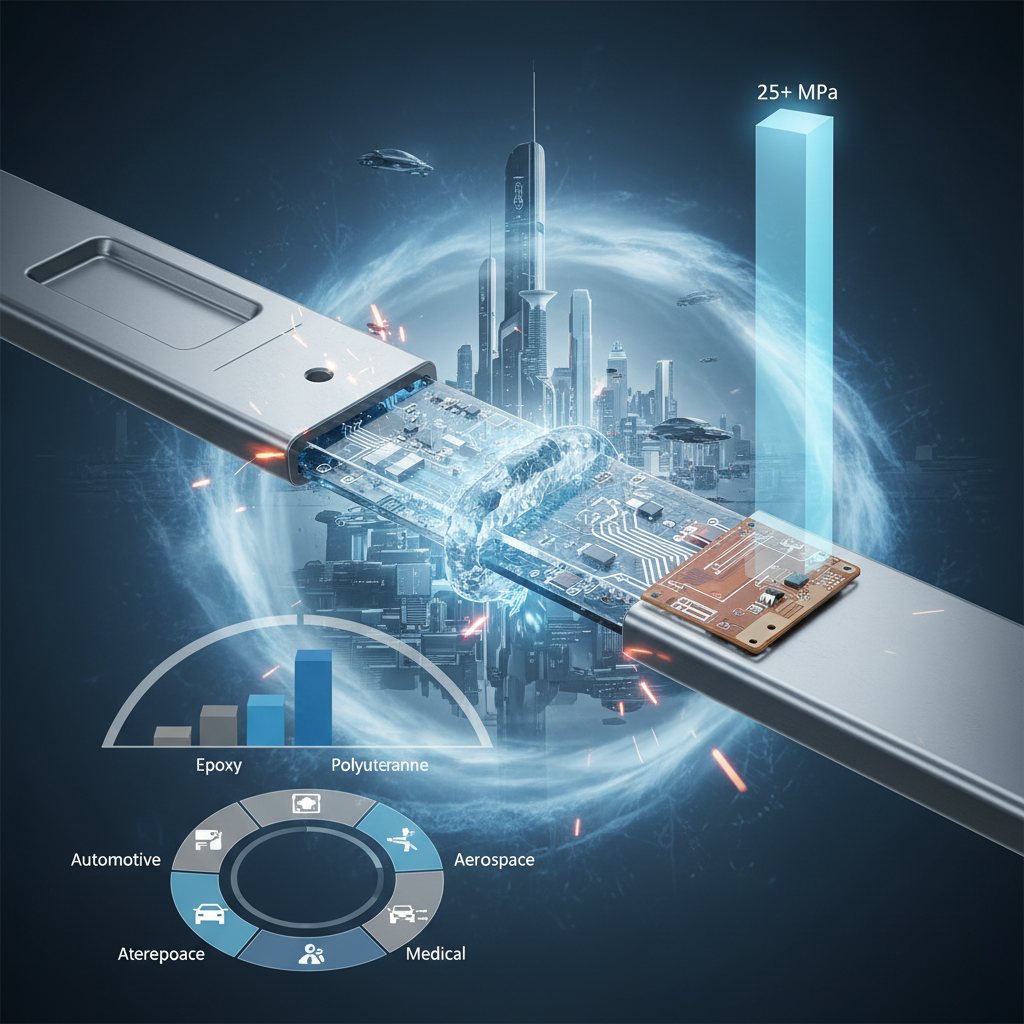

Crylates have emerged as a leading choice in the adhesive market, supported by

statistical insights that highlight their superior performance metrics. According to a 2022 report by the

Adhesive and Sealant Council, crylate adhesives exhibit an impressive bond strength,

often exceeding 25 MPa when tested under various environmental conditions. This strength ensures

that structures bonded with crylate adhesives can endure significant stress, making them ideal for applications spanning

automotive to electronics.

Moreover, the versatility and durability of crylate adhesives are evident in their adhesion to diverse substrates. A recent study found

that crylate formulations provided optimal adhesion levels of 90% or higher across metals,

plastics, and ceramics. This impressive statistic confirms that industry leaders are increasingly turning to these adhesives to enhance

the longevity and reliability of their products.

As industries demand stronger and more resilient bonding solutions, the statistical performance of crylate adhesives positions them as

the ultimate choice for durable applications.

Applications of Crylate Adhesive Across Various Industrial Sectors

Crylate adhesives are gaining traction across various industrial sectors due to their exceptional bonding capabilities and versatility. One of the most significant markets for crylate adhesives is the medical adhesives sector, which is projected to reach a size of USD 12.3 billion by 2026. This growth is driven by the increasing demand for advanced wound care and surgical adhesion solutions, making crylate adhesives a vital component in the medical industry.

Furthermore, the industrial adhesives market is expected to witness substantial growth, progressing from USD 58.8 billion in 2025 to USD 96.7 billion by 2035, at a CAGR of 5.1%. This expansion reflects the rising adoption of crylate adhesives in various applications, including automotive, electronics, and construction. The ethylene butyl acrylate copolymer market is also set to reach USD 623.8 million by 2032, propelled by its usage in packaging and industrial applications, showcasing the adaptability of crylate-based products across different sectors.

As industries continue to evolve, the demand for durable and reliable bonding solutions like crylate adhesives is expected to surge, highlighting their crucial role in modern manufacturing and assembly processes.