What is Crylate Adhesive? Understanding Its Uses and Benefits

Crylate adhesives have emerged as a critical component in various industries, renowned for their exceptional bonding capabilities and versatility. These adhesives, characterized by their unique chemical structure, offer remarkable performance in applications ranging from electronics to automotive manufacturing. According to a recent market analysis by Smithers Pira, the global demand for crylate adhesives is projected to reach $1.35 billion by 2025, driven by their increasing use in high-performance applications.

As noted by Dr. Emily Sanders, a leading expert in adhesive technologies, “Crylate adhesives not only provide superior adhesion but also enhance the longevity and durability of products across multiple sectors.” This statement underscores the significance of understanding crylate adhesives, particularly as industries shift towards more robust and efficient materials. In this article, we will delve into what crylate adhesives are, explore their various uses across different applications, and highlight the benefits they offer in enhancing product performance and sustainability. Through a closer examination, we aim to illuminate the importance of crylate adhesives in driving innovation and efficiency in adhesive application practices.

What is Crylate Adhesive?

Crylate adhesive, also known as cyanoacrylate adhesive, is a type of fast-acting glue that is widely recognized for its ability to bond a variety of materials nearly instantaneously. These adhesives are formed from cyanoacrylate monomers that polymerize quickly when exposed to moisture in the air, creating a strong and durable bond. According to a report by Markets and Markets, the global cyanoacrylate adhesive market is projected to grow at a CAGR of 7.5% between 2021 and 2026, driven by increasing demand from industries such as automotive, electronics, and healthcare.

One of the key benefits of crylate adhesives is their versatility. They can bond materials ranging from plastics and metals to ceramics and wood, making them suitable for numerous applications in both consumer and industrial sectors. Their rapid curing time is especially advantageous in manufacturing processes, where efficiency is critical. The adhesives also exhibit excellent performance in terms of shear strength and flexibility, ensuring that the bonded joints can withstand various stress conditions.

**Tips:** When using crylate adhesives, make sure to properly prepare the surface by cleaning it of dust, oil, and grease to ensure optimal bonding. Additionally, work in a well-ventilated area to avoid inhaling fumes, and consider using small amounts at a time, as the adhesive cures rapidly, reducing the risk of waste.

The Chemical Composition of Crylate Adhesives

Crylate adhesives, a subset of acrylic adhesives, are known for their impressive bonding capabilities and versatility across various industries. Their chemical composition primarily consists of acrylate monomers and cross-linking agents, which contribute to their excellent adhesion properties, heat resistance, and durability. The typical formulation includes a mix of alkyl acrylates, methacrylate, and various polymerization initiators, creating a robust adhesive system suitable for challenging applications.

According to a report by MarketsandMarkets, the global adhesive market is projected to grow significantly, with acrylic adhesives being one of the fastest-growing segments due to their increasing use in automotive and construction sectors. The unique composition of crylate adhesives endows them with superior performance characteristics, such as fast curing times and resistance to environmental factors like moisture and UV rays. These attributes make them highly effective for both indoor and outdoor applications, allowing manufacturers to rely on their stability and longevity.

Furthermore, the versatility of crylate adhesives is highlighted by their ability to bond a wide range of substrates, including plastics, metals, and glass. This adaptability has been shown to enhance production efficiency, as reported by Adhesives & Sealants Industry, which emphasizes the growing adoption of acrylic adhesives in various markets. As industries continue to innovate, the demand for crylate adhesives is expected to rise, making them an essential component in modern adhesive technologies.

Common Applications of Crylate Adhesives in Various Industries

Crylate adhesives are versatile bonding agents widely used across multiple industries due to their unique properties. One of the most common applications is in the automotive sector, where they are employed for bonding trim, glass, and structural components. The fast curing time and excellent adhesion to various substrates make crylate adhesives ideal for enhancing the durability of automotive assemblies, ensuring a reliable performance in challenging environmental conditions.

In the electronics industry, crylate adhesives play a crucial role in the assembly of components. Their ability to bond well with metals, ceramics, and plastics allows for secure and efficient manufacturing of devices such as smartphones and computers. Additionally, these adhesives offer excellent resistance to moisture and heat, making them suitable for applications that require long-lasting performance in high-temperature environments. Overall, the combination of quick curing and strong adhesive properties makes crylate adhesives an invaluable resource in critical manufacturing processes across diverse sectors.

Advantages of Using Crylate Adhesives for Bonding

Crylate adhesives are gaining popularity in various industries due to their unique properties and performance benefits. One of the primary advantages of using crylate adhesives is their exceptional bonding strength. They can bond a wide range of materials, including metals, plastics, and glass, making them versatile for applications in automotive, aerospace, and electronics. The bond formed by crylate adhesives is not only strong but also remains durable under various environmental conditions, such as temperature fluctuations and exposure to moisture.

Another significant benefit of crylate adhesives is their fast curing time. This allows for quicker assembly processes, enhancing overall productivity in manufacturing settings. Additionally, crylate adhesives exhibit low volatility, meaning they emit fewer harmful fumes during application, thus promoting a safer working environment. Their flexibility and resistance to impact further contribute to their reliability, making crylate adhesives an ideal choice for applications that require both strength and flexibility in the bonded joint. By leveraging these advantageous properties, industries can improve both efficiency and product performance.

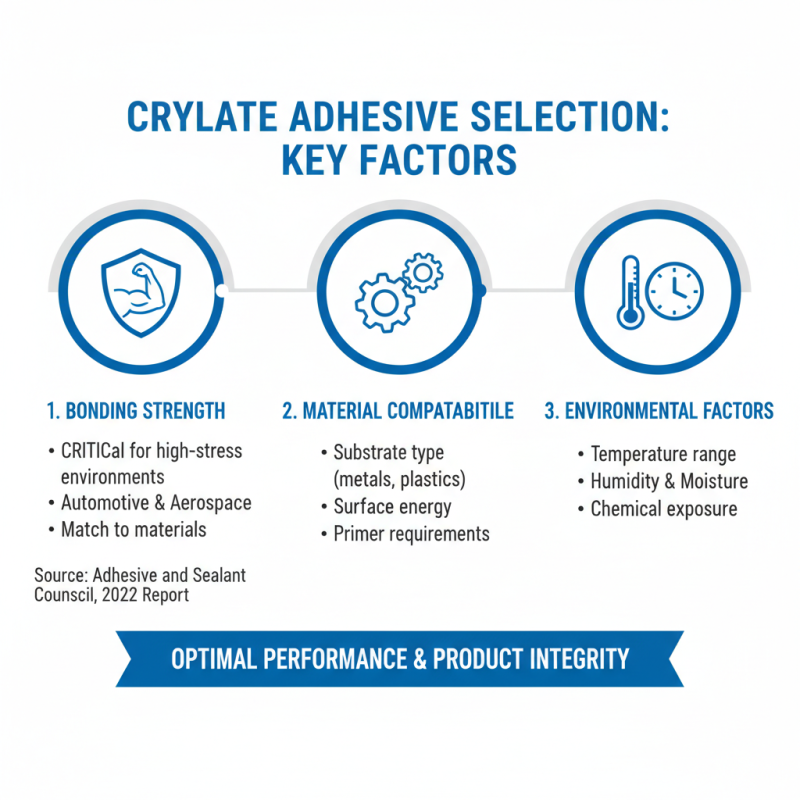

Factors to Consider When Choosing Crylate Adhesives

When selecting crylate adhesives, several critical factors should be considered to ensure optimal performance and suitability for the intended application. Primarily, the bonding strength of the adhesive plays a vital role. According to a 2022 report by the Adhesive and Sealant Council, crylate adhesives are known for their exceptional bonding capabilities, particularly in high-stress environments. This makes them ideal for industries such as automotive and aerospace, where structural integrity is paramount. It's essential to match the adhesive’s strength to the specific materials being bonded, as improper selection can lead to adhesive failure and compromised product integrity.

Another crucial factor is the adhesive's curing time and environmental stability. Crylate adhesives typically offer rapid curing properties, with some formulations achieving full bond strength in a matter of minutes. However, the service temperature and humidity requirements can vary significantly between products. According to a study published in the Journal of Adhesion Science and Technology, optimal performance in varying environmental conditions is often determined by the specific formulation of the crylate adhesive. Users should carefully assess the operating conditions of their projects and select adhesives that ensure reliable performance under those circumstances, to prevent issues like thermal degradation or moisture absorption that could affect the bond’s longevity.