2026 How to Use Modified Acrylate Adhesive Effectively?

Modified Acrylate Adhesive is a versatile bonding solution widely used in various industries. Its unique properties make it suitable for both flexible and rigid materials. Understanding how to use this adhesive effectively can enhance performance and durability.

Proper surface preparation is crucial. Clean surfaces ensure maximum adhesion. Even minor contaminants can lead to bond failure. Applying the adhesive evenly is essential for optimal results. Uneven application might compromise strength.

Consider environmental factors as well. Temperature and humidity influence curing times. Adjusting the application method according to these conditions is necessary. Lastly, always test the bond under expected conditions. This step allows for adjustments and improves reliability. Embracing these practices with Modified Acrylate Adhesive can lead to better outcomes.

Understanding Modified Acrylate Adhesive and Its Properties

Modified acrylate adhesives are gaining traction across various industries due to their versatility and strong bonding capabilities. These adhesives are known for their ability to bond dissimilar materials. For example, a report from the Adhesive and Sealant Council highlights that modified acrylate adhesives can perform well on metals, plastics, and composites. This adaptability makes them ideal for automotive and aerospace applications.

One notable property of modified acrylate adhesives is their rapid curing time. Some formulations can achieve initial bond strength in as little as 10 minutes. However, temperature and humidity can affect the curing process. It’s crucial to understand the environmental conditions during application. Failure to do so might result in a weaker bond or a longer curing time than expected.

While modified acrylate adhesives offer many benefits, challenges remain. Some users report issues with adhesive clarity after curing, which can be problematic for certain applications. Additionally, the shelf life of these adhesives can vary significantly. A closer inspection of the product’s technical data sheets is necessary. It’s important to note that overwriting guidelines might lead to subpar performance. Awareness of these factors can significantly enhance the effective use of modified acrylate adhesives in industrial applications.

Properties and Applications of Modified Acrylate Adhesive

Selecting the Right Modified Acrylate Adhesive for Your Application

Selecting the right modified acrylate adhesive is crucial for achieving effective bonding in various applications. These adhesives are known for their speed of cure and strong adhesion to a wide variety of substrates. According to a report by Smithers Pira, the global demand for modified acrylate adhesives is expected to reach over $2.5 billion by 2025, predominantly driven by the automotive and construction sectors.

When choosing a modified acrylate adhesive, it’s essential to consider the specific application conditions. Factors like temperature, humidity, and surface materials play a significant role in adhesive performance. For example, in the automotive industry, bonds are often subjected to extreme conditions. Inadequate testing can lead to product failure. Adhesives that struggle with temperature fluctuations may break down earlier than expected.

The ideal modified acrylate adhesive should balance strength, flexibility, and curing time. It is vital to understand the limitations of each formulation. Incorrect selection can result in weak bonds or costly rework. Research from the Adhesive and Sealant Council suggests that about 30% of adhesive failures are due to improper selection. Failing to conduct thorough testing phases can jeopardize project success.

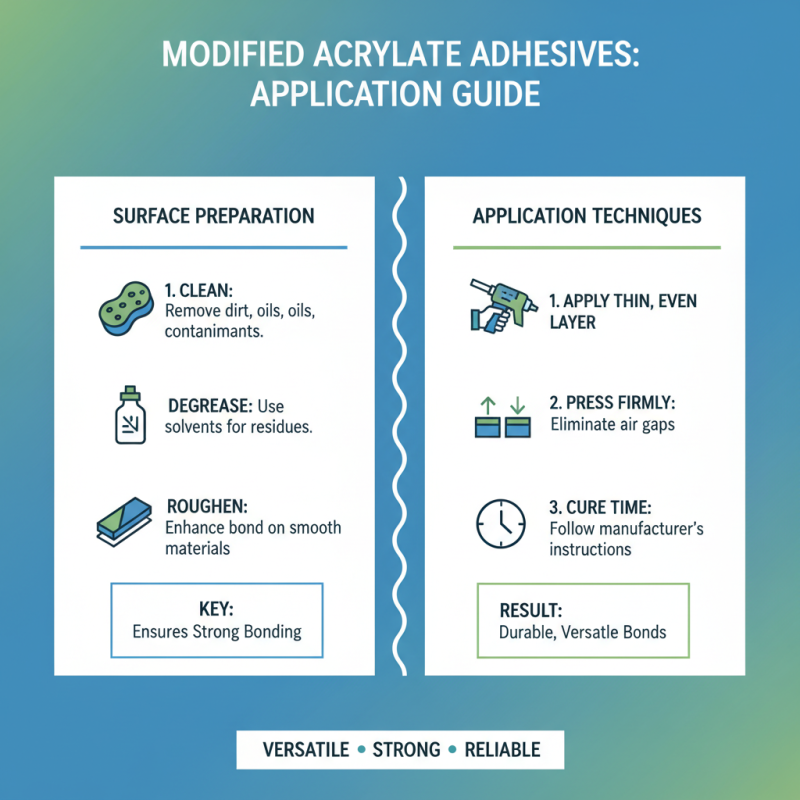

Preparation and Surface Treatment for Effective Adhesion

The effectiveness of modified acrylate adhesive heavily relies on preparation and surface treatment. Proper surface cleaning is crucial. A report by the Adhesive and Sealant Council emphasizes that contaminants can decrease adhesion by up to 50%. Using solvents or specialized cleaners can remove oils, dust, and residues pre-application. This step should not be rushed; even small particles can lead to failure.

Surface roughness plays a pivotal role in adhesion strength. Studies show that surfaces with a higher roughness can enhance mechanical interlocking, significantly increasing bond strength. For maximum effectiveness, consider using abrasives or chemical etching. This can create a textured surface, maximizing contact area. Glossy or smooth surfaces often perform poorly and require more careful treatment. Neglecting this can lead to failures that are hard to trace.

Additionally, humidity and temperature can affect adhesive performance. An analysis from the Journal of Adhesion found that humidity levels can alter curing times significantly. Adapting to environmental conditions is essential. Ignoring these factors can result in unexpected adhesion issues. Monitoring conditions during application minimizes the risk of underperformance. Adjustments may be necessary to attain optimal conditions for bonding.

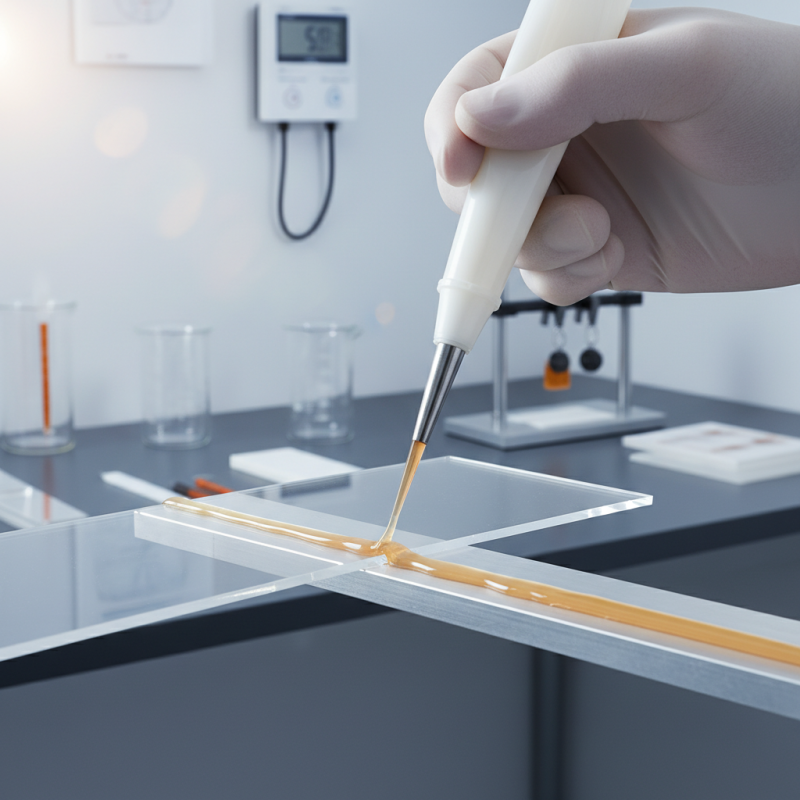

Application Techniques for Modified Acrylate Adhesive

Modified acrylate adhesives are versatile and strong, suitable for various applications. Understanding their application techniques is crucial for effectiveness. Proper surface preparation greatly affects adhesion quality. Ensure surfaces are clean and free of contaminants. Roughening surfaces can enhance the bonding strength, especially on non-porous materials.

Tip: Always test adhesion on small samples before full application. This allows you to assess the bond strength and identify any potential issues. Temperature plays a key role in curing time. Ideally, work within the recommended temperature range of 18-25°C. Curing too quickly can lead to weakened bonds.

Consider environmental factors as well. Humidity and dust can impact adhesion. A controlled environment ensures optimal performance. If you find inconsistencies in bonding, re-evaluate your preparation method. Sometimes, minor adjustments can significantly enhance results. Remember, using modified acrylate adhesive effectively is a combination of technique and attention to detail.

Curing and Handling Tips for Optimal Adhesive Performance

When using modified acrylate adhesive, proper curing and handling are crucial for achieving optimal performance. Industry studies indicate that adhesives cure best at temperatures between 20-25°C. Deviations can lead to incomplete curing. This affects bond strength, leading to failures in applications. It is essential to monitor environmental conditions closely. Poor ventilation can extend curing times and reduce effectiveness.

Handling is equally significant. Always ensure that surfaces are clean and dry before application. Contaminants can impair adhesion. A report from the Adhesive and Sealant Council states that improper surface preparation accounts for 30% of adhesive failures. Additionally, applying too thick a layer can prevent effective curing. Adhering to recommended thickness guidelines can enhance bond quality.

After application, avoid disturbing the materials for at least the recommended period. This allows the adhesive to develop its full strength. Remember that modifications in humidity levels can also impact curing. For instance, high humidity can lead to surface moisture, which may interfere with adhesion. Monitoring these factors can provide insights for better performance. Regular assessments of your curing practices can reveal potential areas for improvement.

Related Posts

-

Top Uses and Benefits of PUR Hot Melt Adhesive in 2025

-

How to Use Polyurethane Adhesive for Strong and Durable Bonds

-

How to Effectively Use PUR Hot Melt Adhesive for Your Projects

-

10 Essential Tips for Using Polyamide Hot Melt Adhesive Effectively?

-

How to Choose the Best Beer Bottle Labeling Adhesives for Your Brewery

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects