How to Effectively Use PUR Hot Melt Adhesive for Your Projects

In the realm of adhesives, PUR Hot Melt Adhesive stands out for its versatility and effectiveness across a variety of applications. As industries evolve and the demand for stronger, more durable bonding solutions increases, understanding how to effectively utilize PUR Hot Melt Adhesive becomes essential for achieving optimal results in your projects. This innovative adhesive not only provides quick setting times but also demonstrates impressive adhesion properties, making it a preferred choice for manufacturers and craftsmen alike.

From woodworking to packaging, the application of PUR Hot Melt Adhesive can significantly enhance the quality and longevity of bonded items. Its unique formulation allows for bonding with porous and non-porous materials, creating a reliable and resilient bond that endures various environmental conditions. By mastering the techniques necessary to work with PUR Hot Melt Adhesive, users can unlock its full potential, ensuring that their projects meet the highest standards of performance.

In this guide, we will explore the best practices for applying PUR Hot Melt Adhesive, including preparation, application methods, and curing processes. Whether you are a seasoned professional or a DIY enthusiast, understanding these key aspects will empower you to take full advantage of this exceptional adhesive, transforming your projects into lasting successes.

Understanding PUR Hot Melt Adhesive: Properties and Benefits

PUR hot melt adhesive, or polyurethane reactive hot melt adhesive, is renowned for its exceptional bonding properties and versatility across various applications. One of the primary benefits of PUR is its ability to bond dissimilar materials, including plastics, wood, and metals, which makes it an ideal choice for industries such as furniture manufacturing, construction, and automotive assembly. The unique chemical composition of PUR allows it to achieve strong bonds even in challenging conditions, such as high humidity or temperature variations.

Another significant advantage of PUR hot melt adhesive is its rapid curing time and high initial tack. This feature ensures that components can be assembled quickly and efficiently, reducing overall production time. Additionally, PUR adhesives exhibit excellent resistance to moisture, chemicals, and temperature fluctuations, which enhances the durability and longevity of the bonded joints. These properties make PUR hot melt adhesives not only cost-effective but also highly reliable for both indoor and outdoor applications, ensuring that projects maintain their integrity and performance over time.

Selecting the Right PUR Hot Melt Adhesive for Your Application

When selecting the right PUR hot melt adhesive for your application, it is essential to consider several factors that can significantly impact both the performance and efficiency of your project. PUR hot melt adhesives are particularly favored in industries such as woodworking and packaging due to their strong bonding capabilities and versatility. According to a recent industry report, the demand for PUR adhesives is expected to grow at a CAGR of 5.6% from 2023 to 2028, highlighting their increasing popularity in various applications.

One of the first considerations should be the specific material you are bonding. PUR adhesives perform well on difficult substrates such as plastics and metal, compared to traditional adhesives. Additionally, evaluate the thermal resistance and moisture resistance required for your project. Research indicates that PUR adhesives can maintain bond strength even in extreme conditions, making them ideal for outdoor applications or environments with fluctuating temperatures.

Tips: Always conduct a preliminary test on the materials to ensure compatibility and adhesion strength before full-scale application. Also, consider the application method—whether you will use a manual gun or an automatic system—as this can influence the choice of adhesive based on its viscosity and melting point. Choosing the right PUR adhesive not only enhances performance but can also lead to cost savings and improved production efficiency.

How to Effectively Use PUR Hot Melt Adhesive for Your Projects

| Application | Adhesive Type | Temperature Resistance | Cure Time | Bond Strength | Unique Features |

|---|---|---|---|---|---|

| Furniture Assembly | PUR Hot Melt | -30°C to 80°C | 1-3 minutes | High Tensile Strength | Moisture Resistant |

| Packaging | PUR Standard | -20°C to 70°C | 30 seconds | Strong Initial Tack | Fast setting |

| Automotive Parts | PUR Structural | -40°C to 100°C | 5-10 minutes | Very High Bond Strength | Chemical Resistant |

| Construction | PUR Exterior | -30°C to 90°C | 10 minutes | Excellent Durability | UV Resistant |

Best Practices for Heating and Applying PUR Hot Melt Adhesive

When using PUR (polyurethane reactive) hot melt adhesive, proper heating and application techniques are essential for optimal performance and bond strength. A study from the Adhesive and Sealant Council indicates that correctly heated PUR adhesives exhibit significantly improved adhesion and durability, with bond strengths up to 30% higher than that of improperly prepared adhesives. For effective use, ensure that the adhesive is heated to the manufacturer's recommended temperature, typically between 120°C and 160°C (248°F and 320°F). This precise heating allows the adhesive to achieve its maximum viscosity, enhancing flow and penetration into substrates.

In addition to temperature control, the method of application plays a crucial role in the efficacy of PUR hot melt adhesives. Research from the Institute of Chemical Technology highlights that using a consistent and uniform application pattern not only minimizes adhesive waste but also optimizes the bonding area, leading to stronger and more reliable joints. Applying the adhesive in a thin, even layer can prevent common issues such as poor adhesion or adhesive migration, which can occur when the adhesive is applied too thickly.

Keeping the work environment free of moisture is also vital, as PUR adhesives are sensitive to moisture levels, which can adversely affect their curing process and final bond strength. By following these best practices, users can ensure that they maximize the performance of PUR hot melt adhesives in their projects.

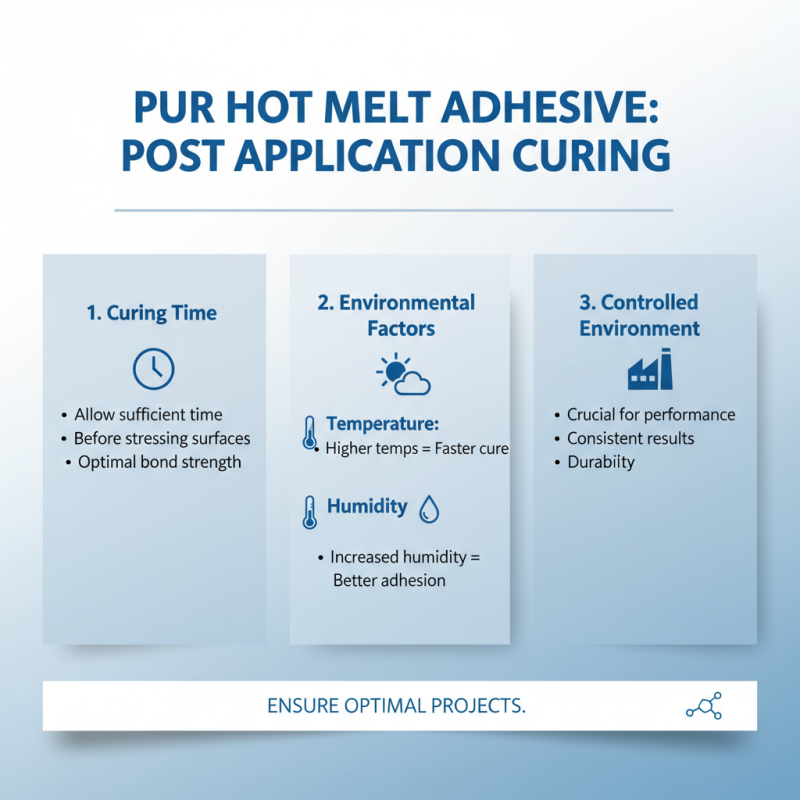

Post-Application Handling and Curing of PUR Hot Melt Adhesive

Post-application handling and curing of PUR hot melt adhesive is crucial to ensure optimal bond strength and durability in your projects. Once the adhesive has been applied, it is important to allow it sufficient time to cure properly before placing any stress on the bonded surfaces. The curing process of PUR adhesive is influenced by environmental conditions, including temperature and humidity. A higher temperature typically accelerates curing, while increased humidity can enhance adhesion properties. Therefore, maintaining a controlled environment can significantly impact the performance of the adhesive.

After application, it is also essential to avoid disturbing the bond as it cures. Care should be taken to minimize any movement or pressure on the adhesive joint during this critical period. Depending on the formulation and application conditions, initial handling strength can be achieved relatively quickly; however, full curing may take several hours or even days. During this time, the adhesive develops its full mechanical properties, which include enhanced resistance to moisture and temperature fluctuations. Following these guidelines for handling and curing will lead to more reliable bonding results in various applications, from woodworking to construction.

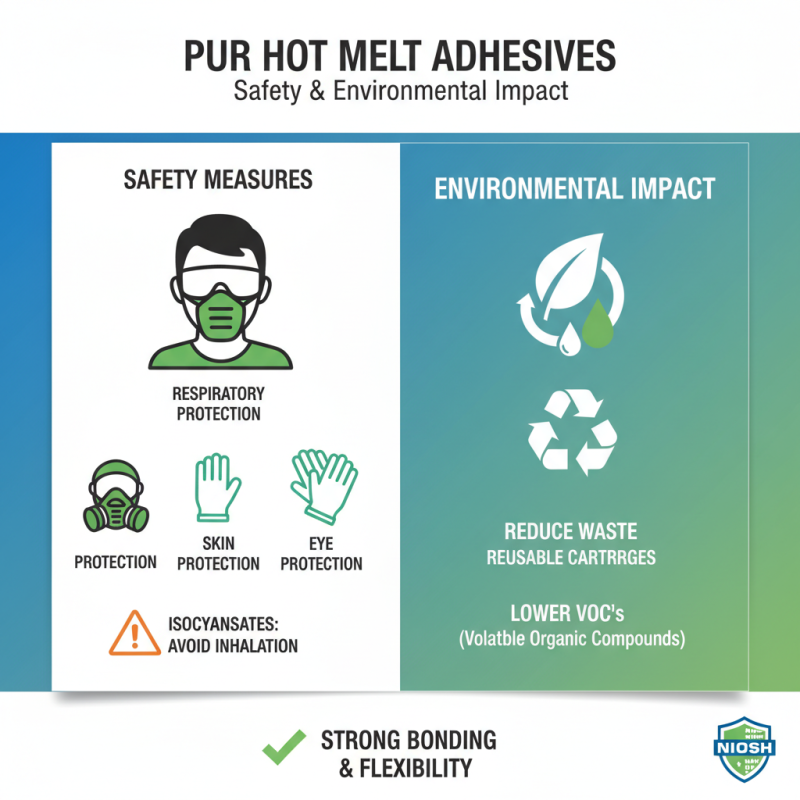

Safety Considerations and Environmental Impact of PUR Adhesives

When utilizing PUR (Polyurethane Reactive) hot melt adhesives, it is crucial to consider both safety measures and the environmental impact. PUR adhesives are favored for their strong bonding capabilities and flexibility across various applications, but they can release isocyanates, which are known to be hazardous when inhaled. According to the National Institute for Occupational Safety and Health (NIOSH), prolonged exposure to isocyanates can lead to respiratory issues and other health problems. Therefore, it is advisable to use appropriate personal protective equipment (PPE) such as masks, gloves, and goggles during application to safeguard against any potential inhalation or skin contact.

Another important aspect is the environmental impact of PUR adhesives. These adhesives are less environmentally friendly due to the inclusion of isocyanates that can contribute to air pollution. Reports from the Environmental Protection Agency (EPA) indicate that strict guidelines are necessary to minimize any adverse effects on air quality during the application process. Opting for low-emission formulations of PUR adhesives can significantly reduce the environmental footprint of your projects.

**Tips:** Always work in a well-ventilated area to mitigate exposure to fumes during the application of PUR adhesives. Consider opting for water-based or bio-based alternatives when possible to reduce your ecological impact while still achieving a strong bond in your projects. Additionally, ensure that you engage in proper disposal methods for any adhesive waste to further minimize environmental concerns.

Related Posts

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

Top Uses and Benefits of PUR Hot Melt Adhesive in 2025

-

How to Use Polyurethane Adhesive for Strong and Durable Bonds

-

How to Choose the Right Crylate Adhesive for Your Project Needs

-

Top Reasons to Choose Modified Acrylate Adhesive for Your Projects

-

What is Crylate Adhesive? Understanding Its Uses and Benefits