What is Polyester Hot Melt Adhesive and Its Key Applications

In the world of adhesives, Polyester Hot Melt Adhesive stands out for its versatility and effectiveness. John Smith, a leading expert in polymer adhesives, states, "Polyester Hot Melt Adhesives provide excellent bonding solutions across various industries." This highlights their broad application potential.

Polyester Hot Melt Adhesive is valued for its quick setting time and strong adhesion. Commonly used in packaging, woodworking, and textile industries, it addresses diverse bonding challenges. Manufacturers appreciate its ability to bond different materials effectively. For instance, it adheres well to plastics and fabrics, making it versatile for product design.

However, the industry faces challenges. Issues like climate resistance and long-term durability can arise with improper use. As users explore Polyester Hot Melt Adhesive, they must understand these complexities. Overall, the benefits are significant, but careful consideration is essential for optimal results.

What is Polyester Hot Melt Adhesive?

Polyester hot melt adhesive is a thermoplastic adhesive made from polyester resins. It is known for its strong bonding capabilities. This type of adhesive melts at a specific temperature and solidifies upon cooling. Its quick setting time allows for fast manufacturing processes, making it popular in various industries.

One key feature of polyester hot melt adhesive is its versatility. It adheres well to different substrates like plastics, textiles, and glass. This makes it ideal for packaging, woodworking, and textile applications. However, it can be sensitive to moisture and heat. This could lead to potential limitations in certain environments.

Despite its strengths, polyester hot melt adhesive is not without flaws. It may not perform well under extreme conditions. Users need to consider its long-term durability. Analyzing these factors is crucial for effective application in projects. Attention to detail is vital when selecting the right adhesive for specific uses.

Chemical Composition and Properties of Polyester Hot Melt Adhesive

Polyester hot melt adhesive (PHMA) is a unique type of thermoplastic adhesive widely used in various industries. Its chemical composition typically comprises polyethylene glycol and terephthalic acid. These elements contribute to its strong bonding capabilities and versatility. PHMA exhibits excellent thermal stability, making it suitable for applications requiring durability under heat. According to a recent market report, the global hot melt adhesive market size is projected to reach USD 8.8 billion by 2027, driven mainly by the growth in the packaging and textile sectors.

Tips: When selecting an adhesive, consider the specific application requirements. Compatibility with materials is crucial. Testing adhesion strength on sample surfaces can help optimize performance.

Polyester adhesives are known for their flexibility and resistance to moisture. This makes them ideal for use in industries such as construction and automotive. However, using PHMA may also have challenges. Sometimes the adhesive's initial tack might be insufficient, leading to misalignment during application. Regular assessments of the adhesive's performance can help mitigate these issues. Understanding the limitations of PHMA is key to achieving optimal bonding outcomes.

In addition to flexibility, PHMA boasts good chemical resistance. It can withstand exposure to oils and solvents, making it suitable for electrical and electronic applications. Despite these advantages, the cost can be a drawback. Users should weigh the benefits against the investment required. Proper training on application techniques is essential for maximizing efficiency.

Key Applications in Industries Using Polyester Hot Melt Adhesive

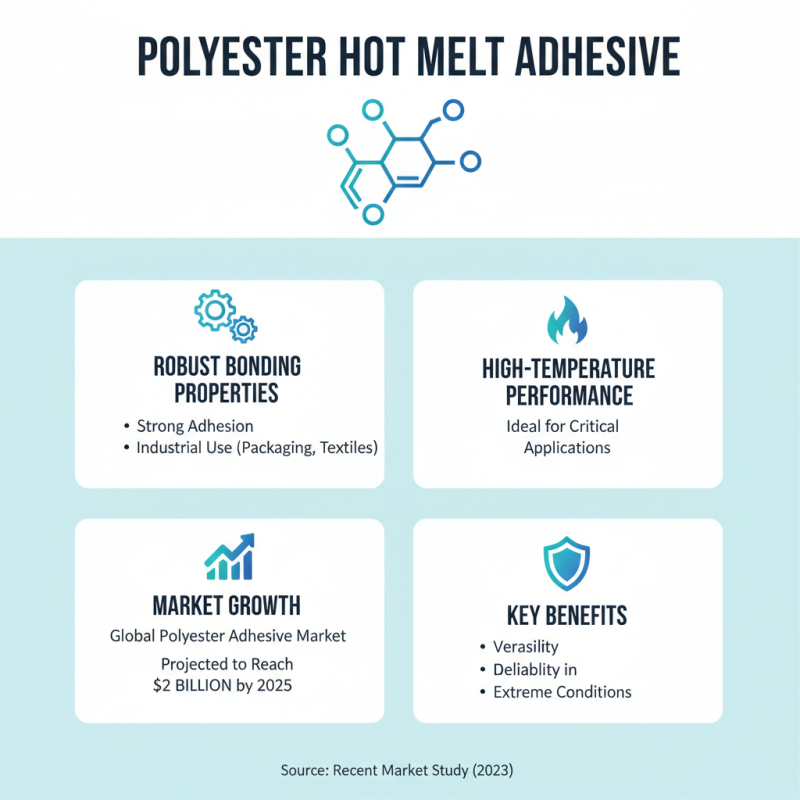

Polyester hot melt adhesive (HMA) is widely recognized in industries for its robust bonding properties. Its applications span various sectors, including packaging and textiles. These adhesives excel in high-temperature environments, making them ideal for critical applications. According to a recent market study, the global polyester adhesive market is set to witness substantial growth, projected to reach $2 billion by 2025.

In the packaging industry, polyester HMAs are often employed due to their quick bonding capabilities. They bond materials like paper and plastic efficiently, ensuring that products remain sealed during transit. The demand for sustainable packaging solutions has further heightened the use of polyester adhesives. However, the environmental impact of some polyester adhesives continues to be a concern. Tackling this issue remains a hot topic among manufacturers.

Textile manufacturing also benefits from polyester hot melt adhesive. This adhesive type is used in garment production to bond fabrics. It facilitates various designs and enhances the durability of clothing. The textile sector is anticipated to grow, with polyester adhesive usage expected to increase by 8% annually over the next five years. Despite its benefits, challenges arise concerning recycling and waste management, emphasizing the need for ongoing innovation in this field.

Advantages of Polyester Hot Melt Adhesive Compared to Other Adhesives

Polyester hot melt adhesive has gained popularity in various industries due to its unique properties. It offers exceptional bonding strength, making it ideal for diverse applications. This adhesive showcases a remarkable versatility across textiles, packaging, and automotive sectors. Many manufacturers prefer it because of its fast setting time and ease of application.

One of the standout features of polyester hot melt adhesive is its superior thermal resistance. Unlike some polyolefin adhesives, it can withstand higher temperatures without losing adhesion. It also provides excellent chemical resistance compared to other types of adhesives. This makes it suitable for environments exposed to moisture and chemicals. Moreover, its bond flexibility allows it to adapt well to different materials, enhancing its functionality.

However, there are challenges. The initial cost can be higher compared to other adhesives. Additionally, it may require specific tools for application, which could limit accessibility for some users. There are also concerns about the potential for brittleness over time. Finding the right balance between performance and cost is crucial, and this can lead to difficult decisions for manufacturers.

What is Polyester Hot Melt Adhesive and Its Key Applications - Advantages of Polyester Hot Melt Adhesive Compared to Other Adhesives

| Dimension | Details |

|---|---|

| Material Composition | Polyester resin and additives |

| Type | Thermoplastic adhesive |

| Common Applications | Textiles, packaging, automotive, electronics |

| Curing Method | Cooling after application |

| Temperature Resistance | Moderate to high, depending on formulation |

| Advantages Over Other Adhesives | Fast setting, flexibility, resistance to moisture |

| Disadvantages | Limited to certain temperatures, can be brittle at low temps |

| Environmental Impact | Recycling options are limited |

Future Trends in Polyester Hot Melt Adhesive Development and Uses

The future of polyester hot melt adhesives is promising. According to a report by MarketsandMarkets, the global market for hot melt adhesives is projected to reach $7.4 billion by 2025. This significant growth can be attributed to rising demand in various industries. Notably, the automotive and packaging sectors are increasingly utilizing these adhesives for their efficiency.

Recent innovations in polyester formulations are enhancing performance. These adhesives are gaining traction due to their superior bonding strength and versatility. However, challenges remain. Some formulations still face environmental concerns. The recycling process for polyester-based products requires improvement. The industry must focus on sustainable practices.

Applications are expanding rapidly. In the electronics industry, polyester hot melts are crucial for assembling components. They provide excellent heat resistance. In furniture manufacturing, they help achieve strong bonds in laminates. This versatility opens new avenues for development. As manufacturers explore novel applications, ongoing research is essential to overcome existing limitations.

Key Applications of Polyester Hot Melt Adhesive

This bar chart illustrates the market share percentage of various key applications of polyester hot melt adhesive. The data shows that the electronics sector holds the largest share, followed by packaging, textiles, automotive, and construction applications.

Related Posts

-

2025 Top Polyester Hot Melt Adhesive Trends and Innovations You Should Know

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

How to Effectively Use PUR Hot Melt Adhesive for Your Projects

-

How to Use Polyurethane Adhesive for Strong and Durable Bonds

-

Top Uses and Benefits of PUR Hot Melt Adhesive in 2025

-

Top Reasons to Choose Modified Acrylate Adhesive for Your Projects