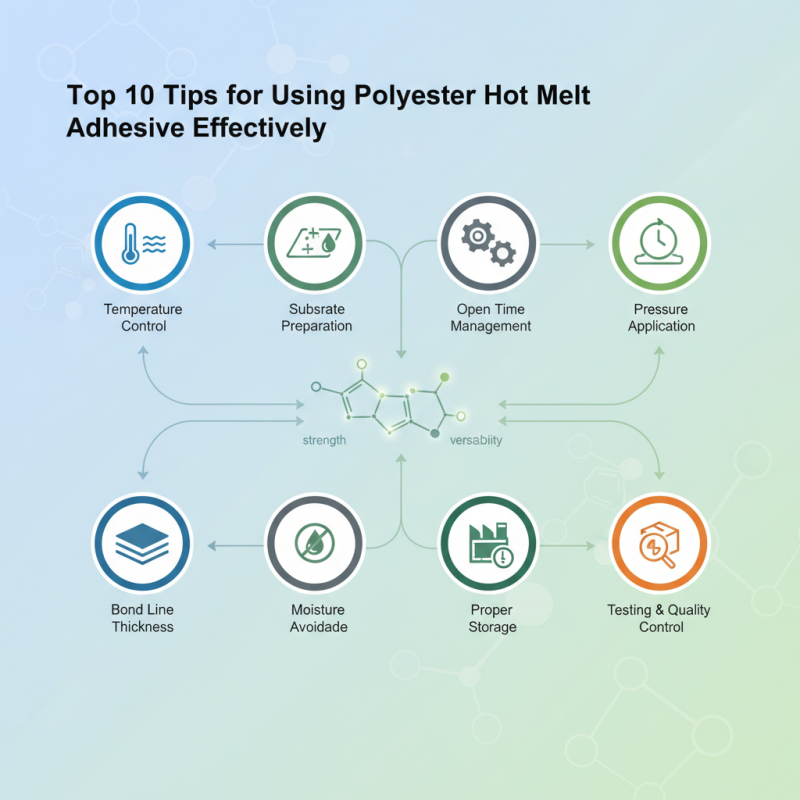

Top 10 Tips for Using Polyester Hot Melt Adhesive Effectively

In the ever-evolving world of adhesive technology, Polyester Hot Melt Adhesive stands out for its versatility and strength. Industry expert Dr. Jane Smith, a prominent researcher in adhesive applications, emphasizes, "The effectiveness of Polyester Hot Melt Adhesive lies in its ability to bond a variety of substrates while maintaining durability and flexibility." This powerful adhesive has gained traction across numerous sectors, from packaging to automotive, prompting users to seek the best practices to maximize its benefits.

Effectively utilizing Polyester Hot Melt Adhesive requires an understanding of its properties and applications. As manufacturers and engineers strive to enhance production efficiency, knowing how to apply this adhesive correctly can lead to improved product performance and longevity. Whether you are new to using hot melt adhesives or looking to refine your techniques, these insights will help you navigate the best practices in the industry, ensuring that your projects achieve the desired results. The following tips will provide valuable guidance for harnessing the full potential of Polyester Hot Melt Adhesive in your applications.

Understanding Polyester Hot Melt Adhesive and Its Applications

Polyester hot melt adhesives (HMA) have gained significant traction across various industries due to their durability and versatility. These adhesives exhibit excellent temperature resistance, making them ideal for applications in automotive, construction, and packaging sectors. According to a report by Markets and Markets, the global hot melt adhesive market is projected to reach $11.49 billion by 2026, with polyester adhesives playing a crucial role due to their strong bonding capabilities and resistance to harsh environmental conditions.

One of the key advantages of polyester hot melt adhesives is their ability to bond a wide variety of substrates, including metals, plastics, and textiles. This adaptability is particularly beneficial in the automotive industry, where different materials need to be securely bonded to withstand vibrations and temperature fluctuations. Furthermore, industry studies indicate that the demand for eco-friendly adhesive solutions is on the rise. Polyester hot melt adhesives can often be formulated with bio-based components, aligning with sustainability trends while still providing superior performance characteristics.

Moreover, the ease of application provided by polyester HMAs contributes to their effectiveness. They can be applied using various methods, such as spraying, rolling, or direct coating, which allows for flexibility in production processes. The adhesive sets rapidly, facilitating quick assembly times in manufacturing environments. According to a recent report by Technavio, efficiency improvements gained through the use of hot melt adhesives can lead to a 20% reduction in production time, illustrating their prominent role in enhancing operational efficiency within manufacturing workflows.

Choosing the Right Polyester Hot Melt Adhesive for Your Project

When selecting the right polyester hot melt adhesive for your project, it's essential to consider the specific requirements of your application. One critical aspect is the temperature resistance of the adhesive. Different projects may require adhesives that perform well under varying temperature conditions, so assessing the operational environment will help in making the correct choice. Additionally, the substrate materials you are working with can greatly influence the adhesive selection. Some polyester hot melt adhesives are specifically formulated to bond well with plastics, while others may be more suitable for wood or textiles.

To ensure you are using polyester hot melt adhesives effectively, here are a couple of tips to keep in mind. First, always conduct adhesion tests before committing to a full application. Testing the adhesive on a small scale can reveal compatibility issues that may arise between the adhesive and the materials. Another helpful tip is to maintain optimal application temperatures. Too low a temperature can lead to poor bonding, while too high might cause the adhesive to degrade. Finding the right balance is crucial for achieving strong, lasting bonds in your work.

Preparation Steps for Optimal Adhesive Bonding Performance

To achieve optimal adhesive bonding performance when using polyester hot melt adhesives, thorough preparation is essential. The initial step is to ensure that the surfaces to be bonded are clean and dry. Contaminants such as dust, grease, or moisture can negatively impact adhesion, leading to weaker bonds. According to a study published in the Journal of Adhesion Science and Technology, contaminants can reduce bond strength by up to 50%, highlighting the importance of surface preparation.

Additionally, the temperature of both the adhesive and the substrates plays a pivotal role in achieving effective bonding. Polyester hot melt adhesives generally perform best when applied at temperatures between 120°C and 180°C. Furthermore, the materials to be bonded should ideally be pre-heated, as this can enhance the flow and penetration of the adhesive, improving overall bond formation. Research conducted by the Adhesive and Sealant Council indicates that maintaining the correct application temperature can lead to bond strengths that are 30% higher compared to those achieved at sub-optimal temperatures. Therefore, adhering to these preparation steps is critical for maximizing the performance of polyester hot melt adhesives in various applications.

Top 10 Tips for Using Polyester Hot Melt Adhesive Effectively

| Tip Number | Tip Description | Expected Outcome |

|---|---|---|

| 1 | Clean Surfaces Thoroughly | Improved bond strength and adhesion |

| 2 | Select Appropriate Adhesive Formulation | Maximized compatibility with materials |

| 3 | Heat Surface Before Application | Enhanced flow and penetration of adhesive |

| 4 | Control Ambient Temperature | Optimal adhesive performance and curing |

| 5 | Use Proper Application Equipment | Uniform adhesive distribution and efficiency |

| 6 | Apply Adhesive Evenly | Consistent bond quality |

| 7 | Allow Sufficient Open Time | Improved joining of components |

| 8 | Apply Pressure during Bonding | Enhanced adhesive flow and contact |

| 9 | Monitor Curing Time | Ensures maximum bond strength |

| 10 | Perform Adhesive Bond Testing | Verify performance and reliability of bond |

Techniques for Applying Polyester Hot Melt Adhesive Effectively

When applying polyester hot melt adhesive, technique is crucial for achieving optimal results. Begin by ensuring that both surfaces to be bonded are clean and dry. Contaminants such as dust or grease can significantly affect adhesion strength. Heating the adhesive to the manufacturer’s recommended temperature is also essential; this ensures proper flow and penetration into the materials, enhancing the bond.

One effective method for application is using a consistent, even bead of adhesive. This not only promotes better adhesion but also minimizes the risk of excess adhesive seeping out from the bonded area. Additionally, working in manageable sections can help you maintain control over the application process and ensure that you have enough time to position the materials correctly before the adhesive sets.

Finally, remember to press the materials firmly together after application. Sufficient pressure encourages a better bond and ensures that the adhesive is evenly distributed between the surfaces. Allowing enough time for the adhesive to cool and cure properly is essential for maximizing bond strength and durability. By following these techniques, you can effectively utilize polyester hot melt adhesive in your projects for reliable results.

Top 10 Tips for Using Polyester Hot Melt Adhesive Effectively

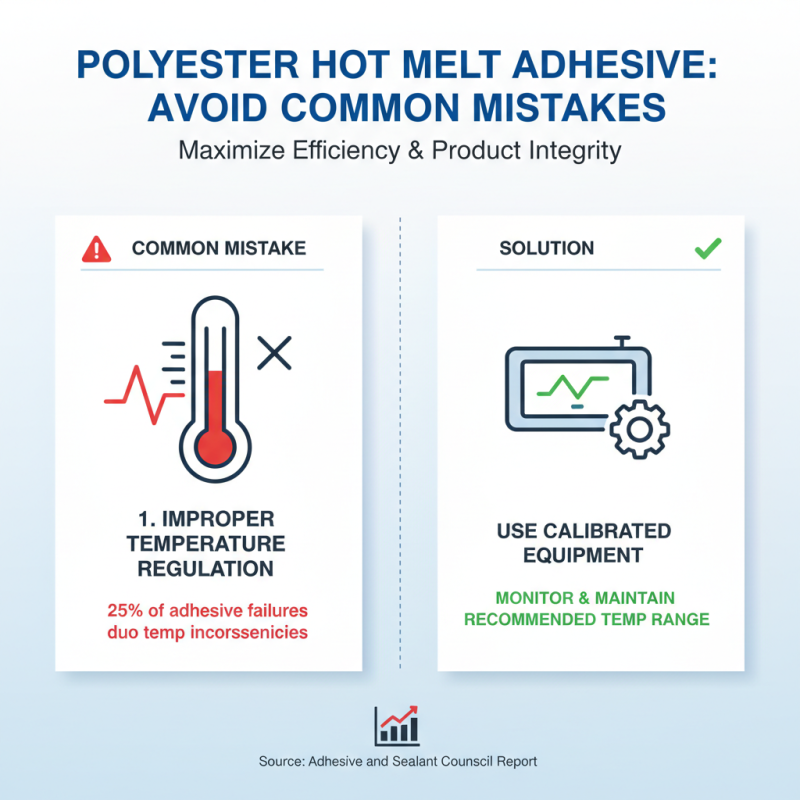

Common Mistakes to Avoid When Using Polyester Hot Melt Adhesive

When utilizing polyester hot melt adhesive, avoiding common mistakes is crucial for maximizing efficiency and ensuring product integrity. One significant error is improper temperature regulation. According to a report from the Adhesive and Sealant Council, approximately 25% of adhesive failures are attributed to temperature inconsistencies during application. Polyester adhesives typically require a specific melting point for optimal bonding. To prevent issues, it's essential to use well-calibrated equipment and to monitor the adhesive temperature closely, ensuring that it reaches and maintains the recommended range for effective adhesion.

Another frequent mistake is inadequate surface preparation. Research published in the Journal of Adhesive Science indicates that nearly 30% of bond failures stem from poorly prepared surfaces. It’s vital to clean, dry, and potentially treat surfaces before applying the adhesive. Contaminants like dust, grease, or moisture can significantly weaken the bond and lead to premature failure. By prioritizing thorough surface preparation, manufacturers can significantly enhance the performance of polyester hot melt adhesives and reduce the likelihood of assembly defects.

Related Posts

-

What is Crylate Adhesive? Understanding Its Uses and Benefits

-

Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions

-

2025 Top Polyester Hot Melt Adhesive Trends and Innovations You Should Know

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

Top Reasons to Choose Modified Acrylate Adhesive for Your Projects