Top Uses of PUR Hot Melt Adhesive in Various Industries?

PUR Hot Melt Adhesive has emerged as a game changer across various industries. According to Dr. Emily Schneider, an expert in adhesive technologies, "PUR Hot Melt Adhesive offers unmatched durability and versatility." Her insight highlights the transforming role of this adhesive in modern manufacturing.

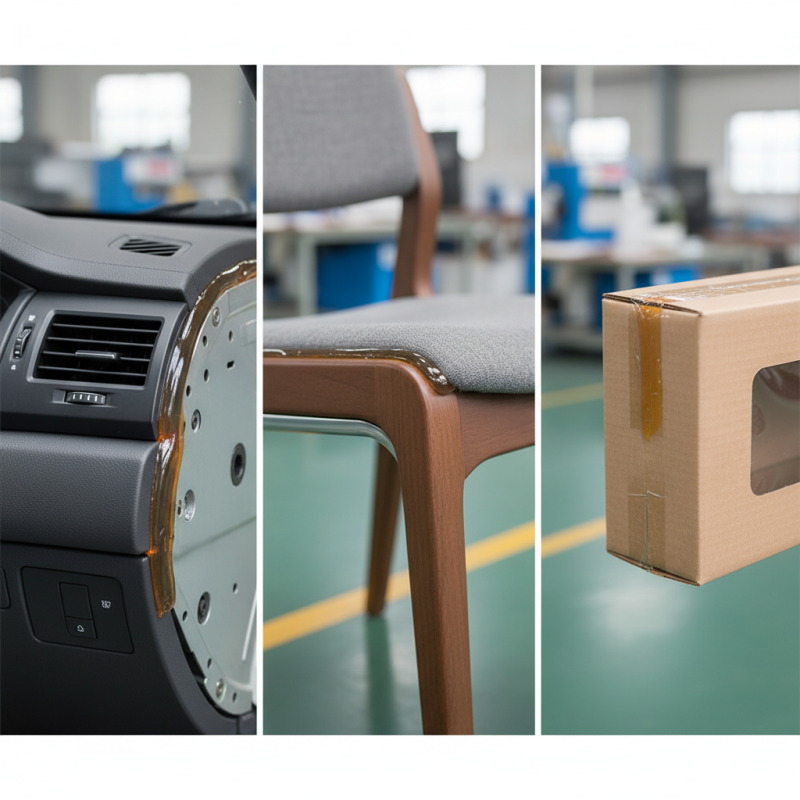

In the automotive industry, PUR Hot Melt Adhesive is increasingly used in interior assembly. Its resistance to heat and moisture improves vehicle longevity. In the furniture sector, this adhesive bonds various materials, creating robust, aesthetically pleasing products. Yet, challenges remain. Manufacturers must ensure the adhesive's performance under different conditions.

Beyond these applications, the packaging industry also benefits. PUR Hot Melt Adhesive provides strong seals, ensuring product integrity. However, the cost of implementation can be a hurdle for small businesses. Balancing quality and budget is essential. As industries adapt, the need for innovation in adhesive solutions continues to grow.

Overview of PUR Hot Melt Adhesives and Their Properties

PUR (polyurethane reactive) hot melt adhesives are gaining popularity in different industries. They are known for their unique properties, enabling strong bonds in varied applications. PUR adhesives cure by reaction with moisture from the air, creating a durable and flexible bond. This feature makes them ideal for challenging environments. They can withstand temperature fluctuations and maintain their adhesive strength.

One significant advantage of PUR hot melts is their versatility. They can bond dissimilar materials, such as plastics, wood, and metals. This capability opens up many possibilities in manufacturing and construction. However, not all applications may yield excellent results. Some substrates may require surface preparation for optimal adhesion. Users should consider that every material behaves differently during bonding.

The curing time of PUR adhesives can also vary. Factors like humidity and temperature affect how quickly the bond forms. Sometimes, users might experience frustration due to unexpected delays in curing. It is crucial to conduct tests to determine the ideal conditions for each specific case. Proper application techniques should be emphasized to ensure adherence to safety and performance standards. Experimentation with small batches could help identify the best approach in real-world scenarios.

Top Uses of PUR Hot Melt Adhesive in Various Industries

| Industry | Application | Properties | Benefits |

|---|---|---|---|

| Automotive | Bonding interior parts | High heat resistance, flexibility | Durability, shock absorption |

| Furniture | Laminating surfaces | Excellent adhesion, water resistance | Long-lasting bonds, minimal swelling |

| Packaging | Sealing cartons | Quick curing time, strong bond | Increased efficiency, reduced wastage |

| Electronics | Assembly of components | Dielectric properties, thermal resistance | Reliability, improved performance |

| Textiles | Adhesive bonding for garments | Flexibility, resistance to washing | Comfort, longevity of use |

Key Industries Using PUR Hot Melt Adhesive Solutions

PUR hot melt adhesive is gaining traction across various industries for its unique properties. In the packaging sector, it offers strong bonding and flexibility. Reports indicate that the demand for hot melt adhesives in packaging will reach over $9 billion by 2025. This growth is attributed to the rising need for sustainable packaging solutions that are efficient and eco-friendly.

The woodworking industry also utilizes PUR adhesives extensively. They provide excellent moisture resistance, making them ideal for furniture and flooring. According to market analyses, the woodworking adhesive market is expected to grow at a compound annual growth rate (CAGR) of 4.5% through 2026. However, the cost of raw materials can impact production budgets and pricing strategies.

In the automotive field, PUR adhesives excel in various applications, from bonding interior components to sealing assemblies. Data shows that the automotive adhesives market will surpass $4 billion by 2024. Yet, the industry faces challenges in achieving perfect adhesion under multiple environmental conditions. Understanding these limitations is crucial for effective application.

Advantages of PUR Hot Melt Adhesives in Manufacturing Processes

PUR (Polyurethane Reactive) hot melt adhesives have become increasingly popular in manufacturing due to their unique properties. These adhesives offer exceptional bond strength and flexibility. According to a recent industry report, the PUR adhesive market is expected to grow by 7.5% annually from 2021 to 2026. This growth reflects the rising demand across various sectors, especially in furniture and automotive manufacturing.

The advantages of PUR adhesives are noteworthy. They perform well under harsh conditions and resist moisture and temperature variations. A study highlighted that PUR adhesives typically maintain over 70% of their initial strength even after exposure to water. However, manufacturers must address the challenges of application methods. Some processes can create difficulties in handling, and operators need proper training to maximize efficiency.

Furthermore, the curing time can vary based on environmental humidity. This inconsistency can lead to delays in production schedules. A report from the Adhesive and Sealant Council noted that risk management is crucial when integrating PUR adhesives into operations. Companies are encouraged to evaluate their processes regularly to ensure optimal performance and safety protocols are in place.

Innovative Applications of PUR Hot Melt Adhesives in Packaging

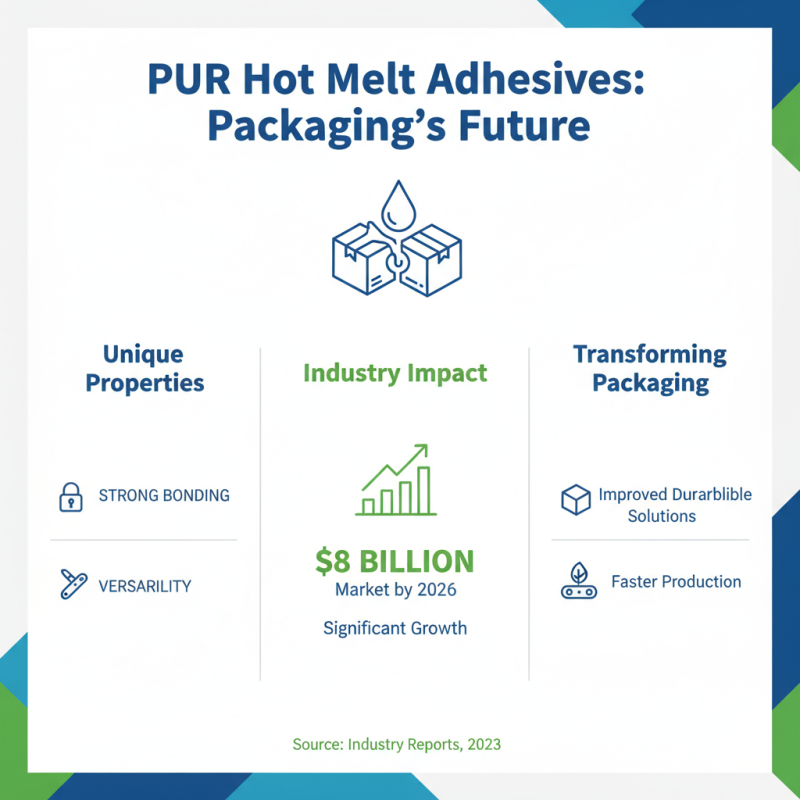

PUR hot melt adhesives are transforming the packaging industry with their unique properties. These adhesives are known for their strong bonding capabilities and versatility. Recent industry reports indicate that the market for hot melt adhesives, including PUR, is expected to grow significantly, reaching approximately $8 billion by 2026. This growth highlights their increasing importance in various applications.

In packaging, PUR adhesives excel in providing moisture and heat resistance. This makes them ideal for sensitive products like food and pharmaceuticals. According to data from market analysis, over 40% of PUR adhesive usage is in packaging applications. Companies are adopting these adhesives to enhance product integrity and shelf life. However, while the benefits are clear, some manufacturers struggle with the curing time. A lack of proper handling can also lead to adhesion failures, requiring further quality checks.

Additionally, the shift towards eco-friendly solutions has prompted a reevaluation of adhesive formulations. PUR adhesives are often praised for their lower environmental impact compared to traditional options. Yet, some users find the initial cost to be higher. Balancing performance and sustainability can be challenging. As the sector evolves, innovators need to focus on creating more efficient solutions without compromising on quality. This balance may redefine how the packaging industry harnesses the power of PUR adhesives moving forward.

Future Trends in the Use of PUR Hot Melt Adhesives Across Industries

As industries evolve, PUR hot melt adhesives are gaining traction across various fields. Reports indicate that the global market for these adhesives is projected to reach over $3.5 billion by 2026. This growth is driven by their versatility and efficiency in bonding. Future trends show an increasing shift toward developing bio-based PUR adhesives to meet sustainability goals.

In the automotive industry, PUR adhesives are changing the game. They provide stronger bonds and quicker assembly times. This minimizes production delays, a vital aspect as manufacturers strive for efficiency. Additionally, the construction sector is likely to incorporate PUR adhesives for insulation and as weather barriers. These applications ensure durability and energy efficiency, aligning with green building principles.

Tip: Regular assessment of adhesive performance can enhance product effectiveness. Monitor bonding strength over time to identify potential areas for improvement. Small adjustments can significantly impact the overall application.

The packaging industry is also adapting. A focus on eco-friendly solutions drives demand for PUR adhesives. This shift comes amid increased scrutiny over plastic use. Companies are rethinking their material choices and considering the lifecycle of their products. Yet, challenges remain. Maintaining performance while ensuring environmental compliance is not straightforward. Progress requires innovation and collaboration.

Top Uses of PUR Hot Melt Adhesive in Various Industries

This chart illustrates the top uses of PUR hot melt adhesive across various industries, highlighting the market share for each sector. The furniture and packaging industries are leading in the utilization of PUR adhesives, showcasing its versatility and effectiveness.

Related Posts

-

How to Effectively Use PUR Hot Melt Adhesive for Your Projects

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

What is Polyester Hot Melt Adhesive and Its Key Applications

-

10 Essential Tips for Using Polyamide Hot Melt Adhesive Effectively?

-

2026 Best Polyester Hot Melt Adhesive Options for Your Projects?

-

Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions