How to Use Polyurethane Adhesive for Strong and Durable Bonds

In the realm of construction and manufacturing, the significance of strong and durable bonds cannot be overstated. With the widespread demand for reliable adhesives, Polyurethane Adhesive has emerged as a leading choice among industry professionals. John Smith, a renowned expert in adhesive technologies, states, "When it comes to creating lasting bonds, Polyurethane Adhesive stands out due to its versatility and strength." This statement encapsulates the essence of why many craftsmen and builders are turning to this innovative solution.

Polyurethane Adhesive not only offers exceptional bonding capabilities across a variety of materials but also boasts unique properties that enable it to withstand environmental challenges. Its resilience against moisture, temperature fluctuations, and chemical exposure makes it an ideal option for both indoor and outdoor applications. As the construction industry evolves, understanding the proper usage of Polyurethane Adhesive becomes essential for achieving high-quality results that endure over time.

In this guide, we will explore the effective techniques for applying Polyurethane Adhesive, ensuring that you can harness its full potential for creating robust and durable bonds. Whether you're a seasoned professional or a DIY enthusiast, mastering the use of this adhesive will elevate the quality of your projects and enhance their longevity.

Understanding Polyurethane Adhesive: Properties and Benefits

Polyurethane adhesives are known for their exceptional bonding capabilities, making them a preferred choice for a wide range of applications. One of the defining characteristics of polyurethane adhesive is its versatility; it can bond various materials, including wood, metal, plastics, and ceramics. The adhesive forms a strong, flexible bond that can withstand a significant amount of stress and movement, which is ideal for projects subject to temperature fluctuations or moisture. This flexibility is crucial in ensuring that the integrity of the bond is maintained over time.

In addition to their strong bonding properties, polyurethane adhesives also exhibit excellent resistance to environmental factors. They are resistant to water, chemicals, and UV light, which makes them suitable for both indoor and outdoor applications. This durability contributes to the longevity of the bonded materials, reducing the need for frequent repairs or replacements.

Moreover, polyurethane adhesives expand slightly upon curing, allowing for a tighter bond between surfaces and filling gaps where other adhesives might fail. These properties make polyurethane adhesives not only reliable but also a practical choice for crafting and construction, ensuring strong and durable bonds that stand the test of time.

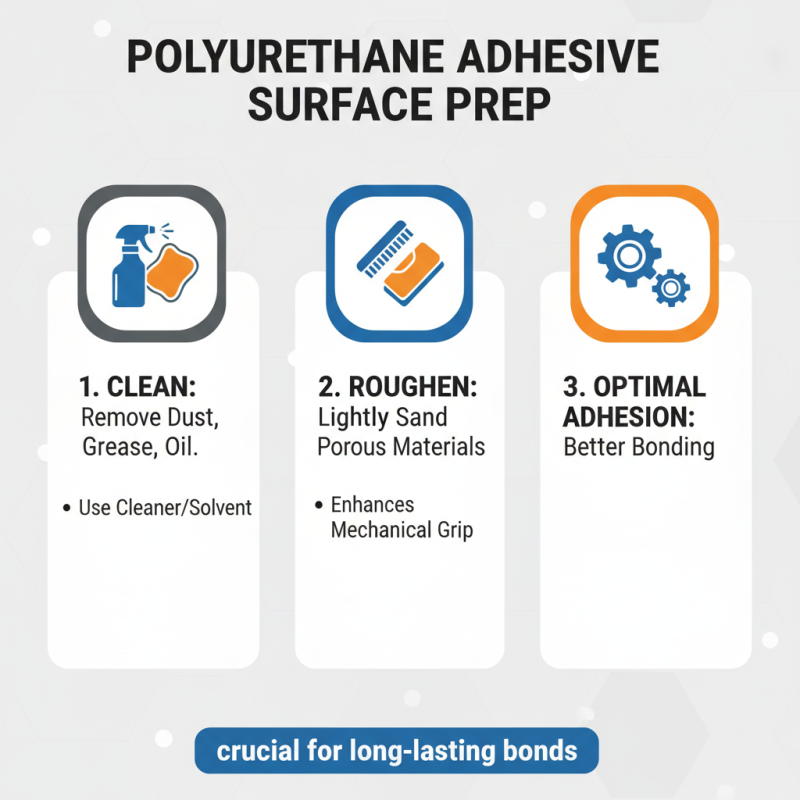

Preparing Surfaces for Optimal Adhesion Using Polyurethane

Preparing surfaces properly is crucial for achieving optimal adhesion when using polyurethane adhesive. Begin by ensuring that the surfaces are clean and free from dust, grease, oil, and any other contaminants. Use a suitable cleaner or solvent to thoroughly wipe down the areas to be bonded. For porous materials, it might be beneficial to sand the surface lightly, creating a rough texture that promotes better bonding. This step enhances the mechanical grip of the adhesive, allowing it to penetrate into the material more effectively.

Once the surfaces are clean and prepped, it’s important to consider moisture levels. Polyurethane adhesives are sensitive to moisture; therefore, ensure that the surfaces are dry before application. If working with wood or other natural materials, allowing them to acclimate to the environment can help in achieving maximum adhesion. Finally, follow the manufacturer’s guidelines regarding application conditions and setup time to ensure that the adhesive bonds properly and provides the desired strength and durability for your project.

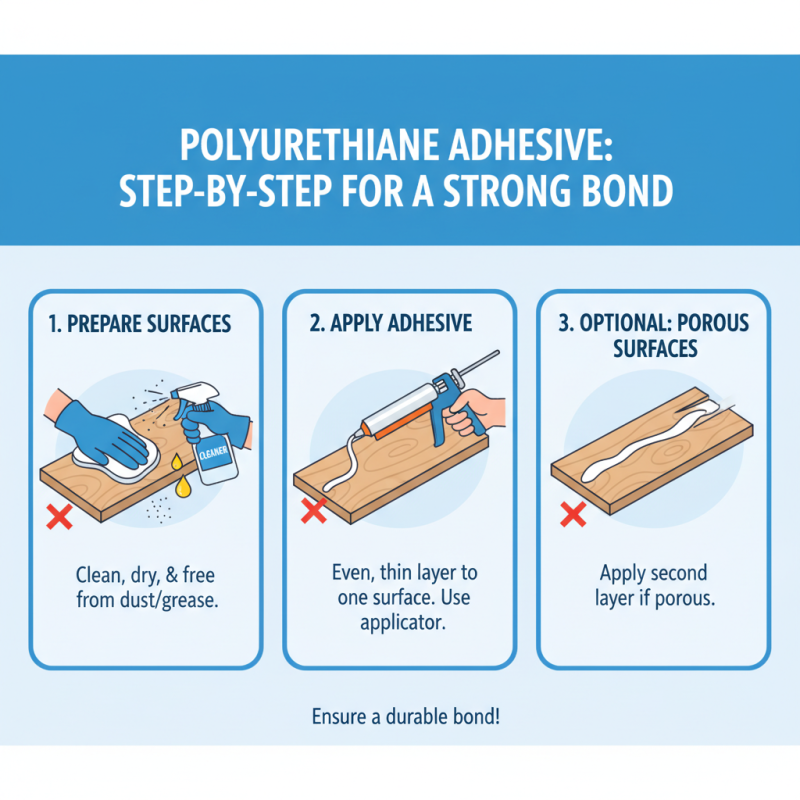

Step-by-Step Application of Polyurethane Adhesive

When working with polyurethane adhesive, the key is to follow a step-by-step process to ensure a strong and durable bond. Begin by preparing your surfaces; they should be clean, dry, and free from dust or grease. This preparation allows the adhesive to adhere properly. Next, apply the polyurethane adhesive evenly on one of the surfaces using a suitable applicator. It’s best to use a thin layer for optimal bonding strength. If the surfaces are porous, consider applying a second layer after the first has a chance to set slightly.

After applying the adhesive, align your pieces carefully before pressing them together. Allow them to bond under pressure for the recommended time, which can typically range from a few minutes to several hours, depending on the project requirements. It's essential to clamp the materials if necessary, as this ensures a stronger and more reliable bond.

**Tips:** Always wear gloves when handling polyurethane adhesive, as it can be difficult to remove from skin. Additionally, working in a well-ventilated area is crucial to avoid inhaling fumes. Finally, remember that polyurethane adhesive expands slightly as it cures, so avoid excessive application to prevent mess and ensure a clean finish.

Curing Time and Environmental Considerations for Polyurethane

The curing time of polyurethane adhesive is a critical factor that impacts the overall performance and durability of the bond. Typically, the curing process begins after the adhesive has been applied, and it can vary significantly depending on environmental conditions such as temperature and humidity. According to the Adhesive and Sealant Council, a leading industry organization, the optimal curing temperature for polyurethane adhesives ranges from 70°F to 80°F (21°C to 27°C). Under these conditions, full curing can take anywhere from 24 hours to several days, depending on the substrate and thickness of the adhesive layer. In colder or more humid environments, the curing time can be prolonged, sometimes necessitating additional moisture to facilitate the process.

Environmental considerations also play a significant role in the use of polyurethane adhesives. As they often emit volatile organic compounds (VOCs) during curing, proper ventilation is essential to ensure worker safety and compliance with health regulations. Industry reports indicate that exposure to high levels of VOCs can lead to respiratory issues and other health problems, highlighting the importance of using these adhesives in well-ventilated spaces. Moreover, sustainability efforts are pushing manufacturers toward developing low-VOC and eco-friendly formulations, reducing environmental impact while maintaining performance standards. Understanding these aspects can help professionals select the right polyurethane adhesive for their applications while adhering to safety and environmental guidelines.

Maintenance and Care for Long-lasting Bonds with Polyurethane

When working with polyurethane adhesive, proper maintenance and care are crucial for ensuring long-lasting bonds. One of the foremost aspects is allowing appropriate curing time before putting any stress on the bond. Curing can take anywhere from a few hours to a full day, depending on environmental conditions. Adequate ventilation and optimal temperature can expedite this process, reinforcing a strong and reliable bond.

Tips: Always ensure that the surfaces to be bonded are clean and free of dust or grease. Use a solvent like isopropyl alcohol for cleaning, as it helps achieve a better adhesion surface. Additionally, avoid applying excessive pressure while the adhesive is curing, as this can compromise the bond strength.

To further extend the life of your bonds, consider applying a protective sealant after the adhesive has completely cured. This can shield the bond from moisture, UV radiation, and other environmental stressors that might weaken it over time. Regularly check the bonds for any signs of wear or damage, and address issues promptly to maintain the integrity of your projects.

Related Posts

-

What is Crylate Adhesive? Understanding Its Uses and Benefits

-

How to Choose the Right Crylate Adhesive for Your Project Needs

-

Top Reasons to Choose Modified Acrylate Adhesive for Your Projects

-

Why Crylate Adhesive is the Ultimate Choice for Durable Bonding Solutions

-

How to Choose the Best Polyamide Hot Melt Adhesive for Your Projects

-

How to Choose the Best Beer Bottle Labeling Adhesives for Your Brewery